|

|

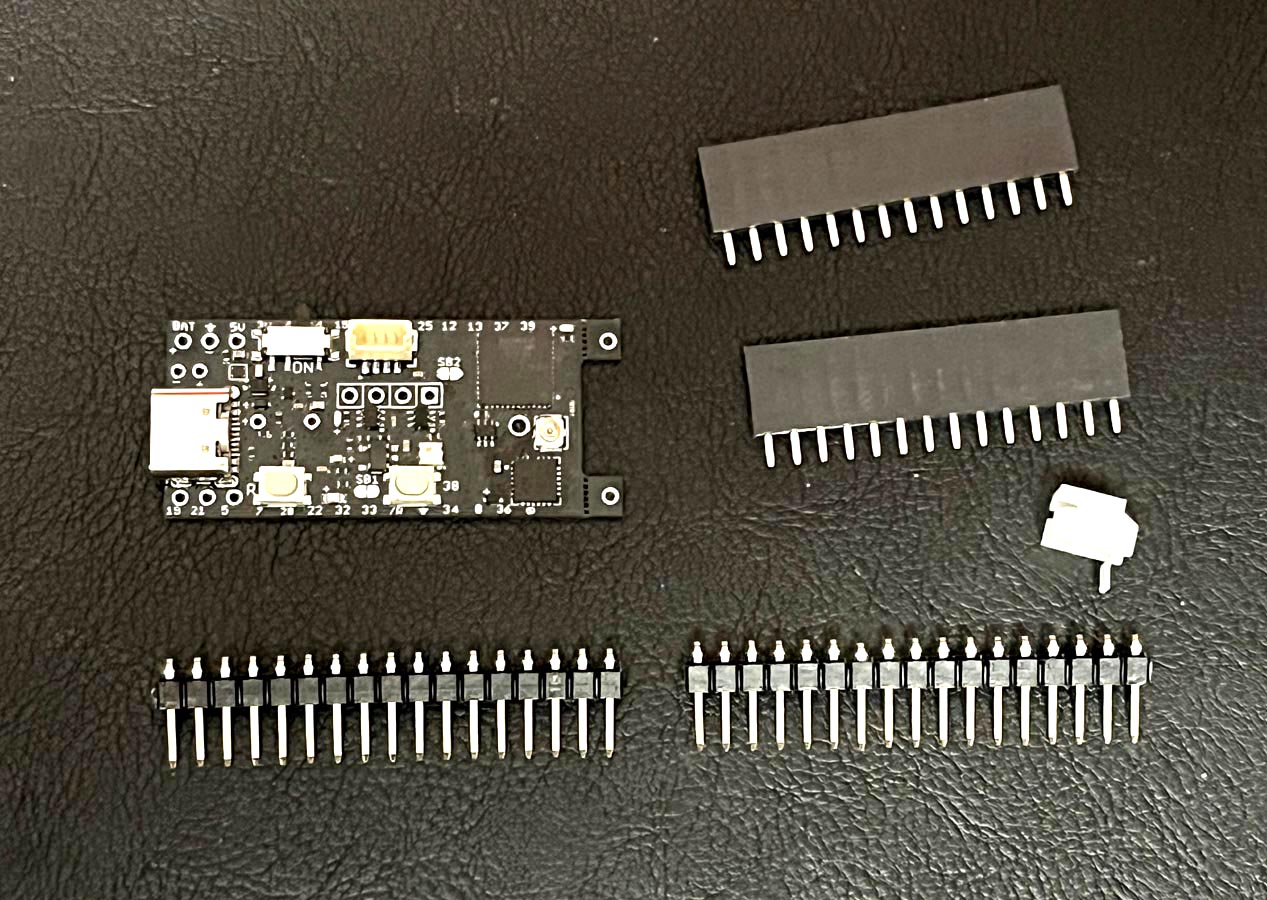

1. Parts included in the package:

One

NanoboyPICO-V3-02 board.

Two 1x17 right-angle male headers.

Two 1x14 female headers.

One

2-pin JST connector, 2mm pitch.

|

|

|

|

|

|

|

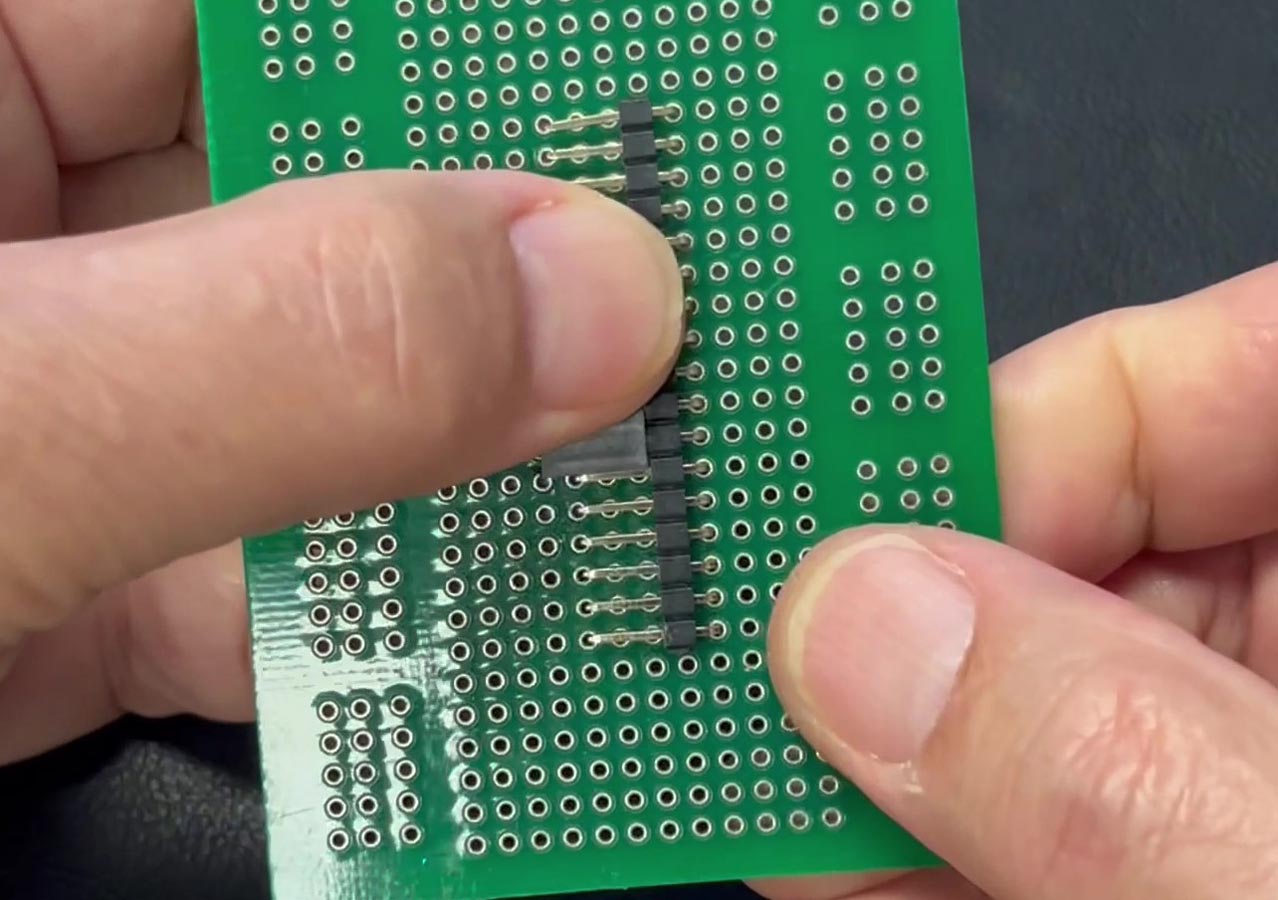

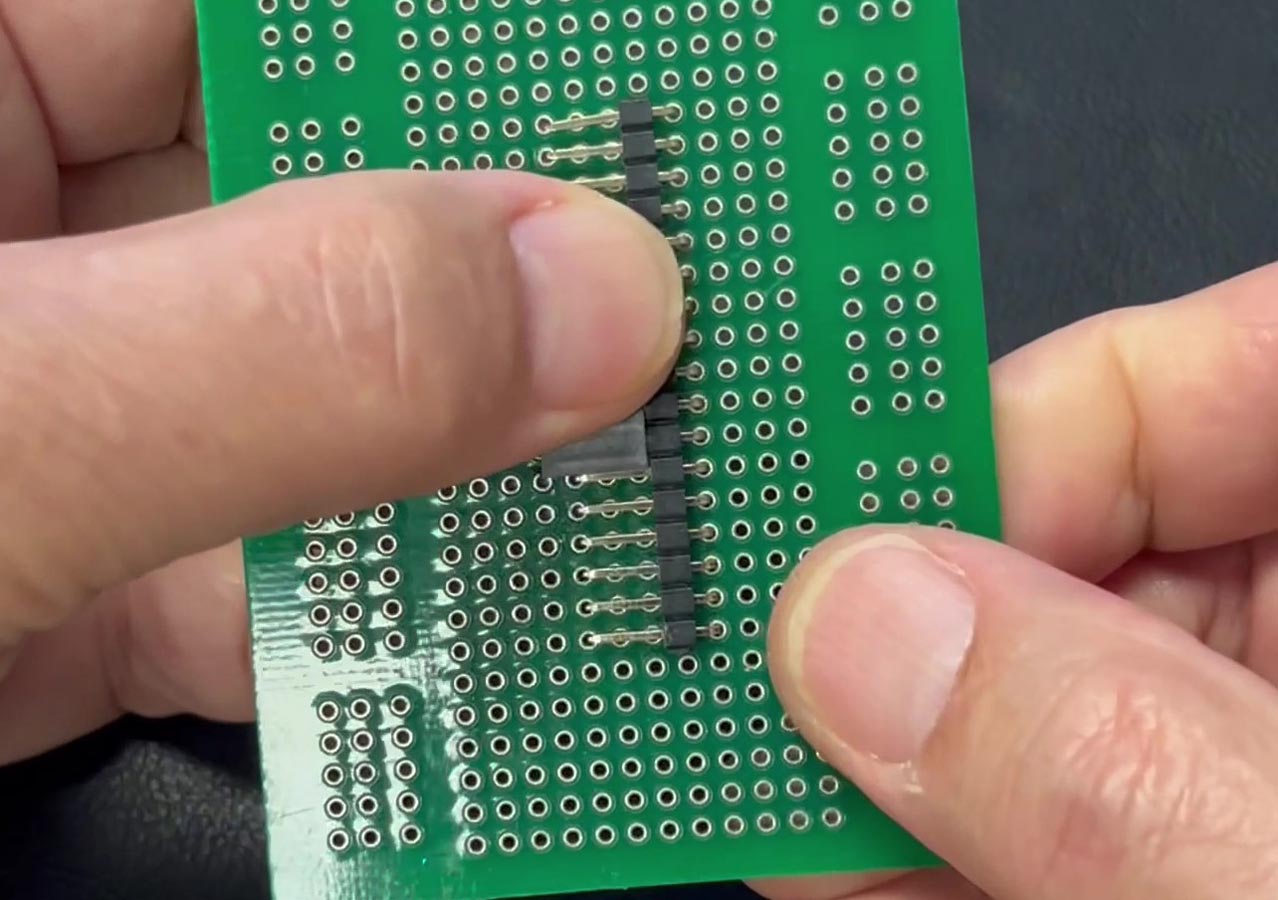

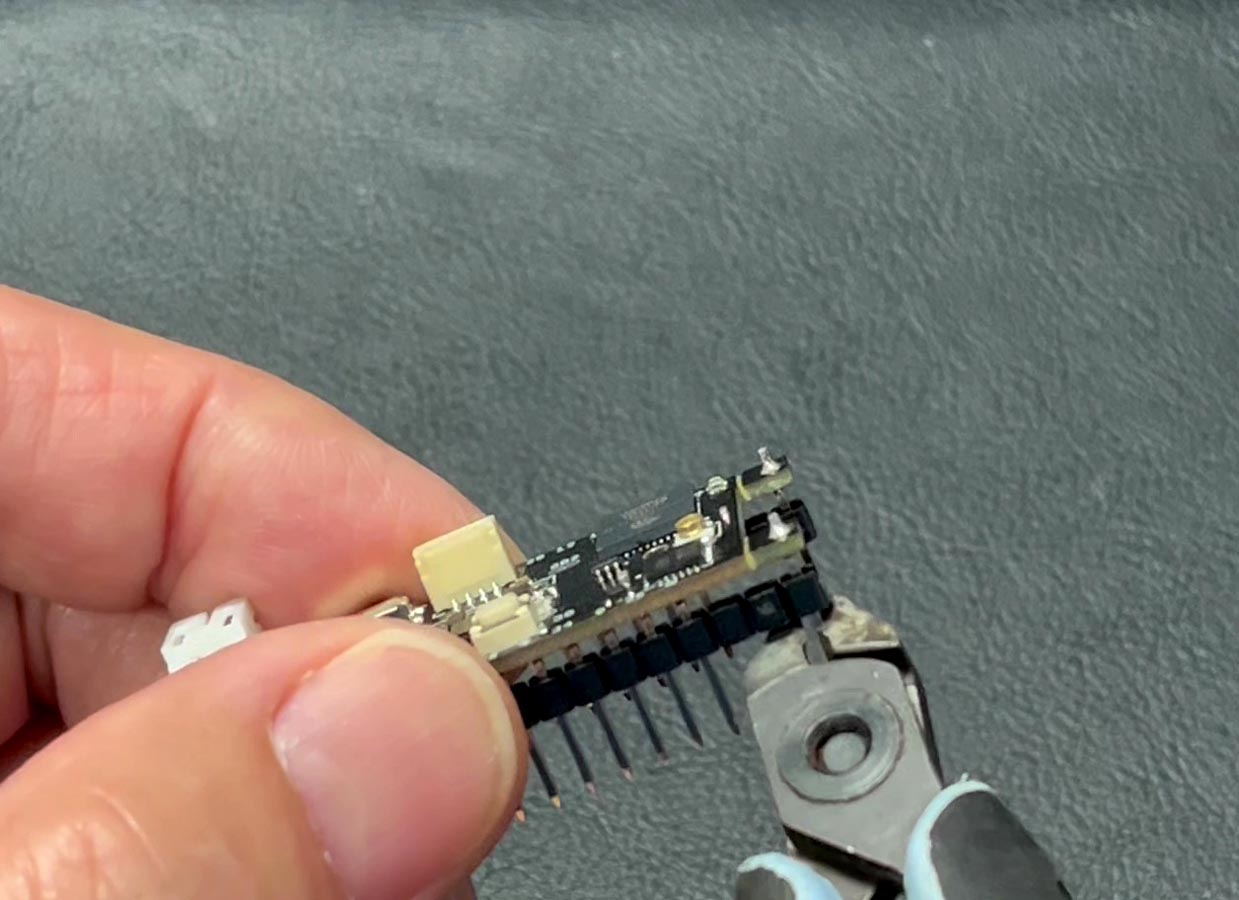

2 Place the shorter end of the 1x17 right

angle male header on a prototype PCB.

The length of the pin is longer than 1.6mm. So

flush cut the 16 pins to the PCB to make the

length shorter.

See the video clip |

|

|

|

|

|

|

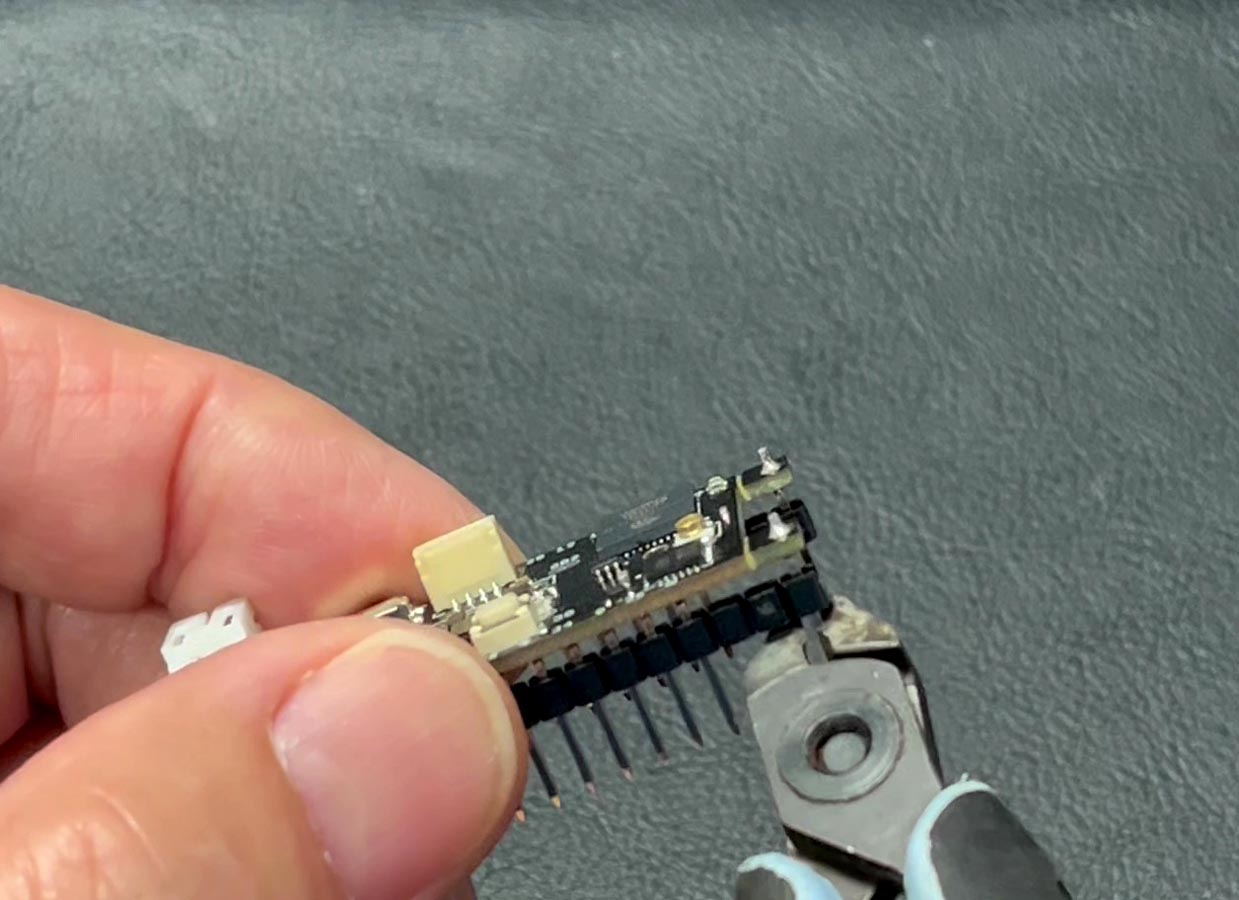

3 Bend 3 pins on each end of the 1x17 male

header and make them straight.

place them on a table as shown on the

picture.

Be sure to place the long pins in the middle.

Use a pair of pliers to pull out 2 pins next to the right-most pin out

of each header as shown on the picture.

The right-most pin is a helper-pin for securing

the header position during soldering. It will be

broken off after soldering is done.

See the video clip

|

|

|

|

|

|

|

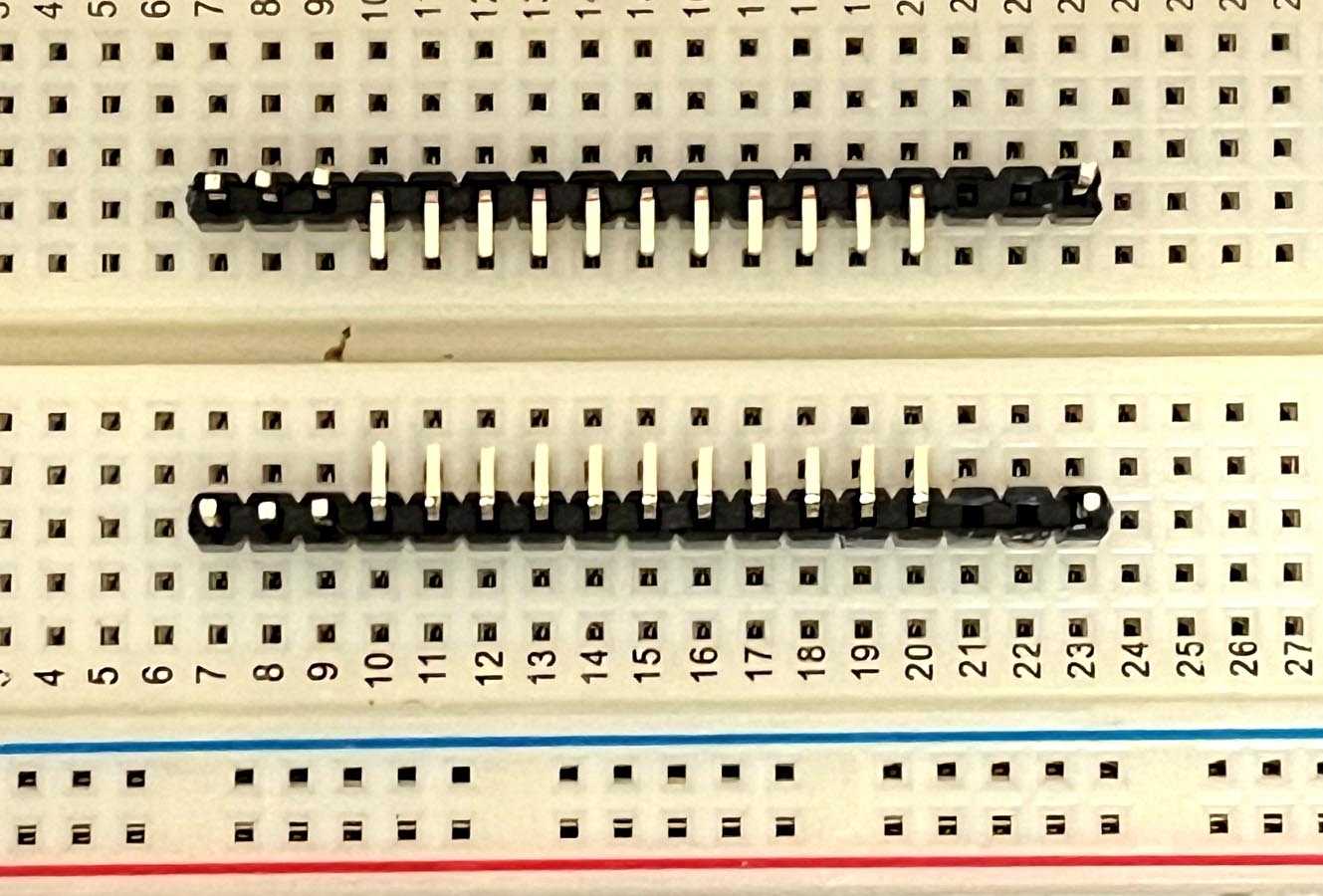

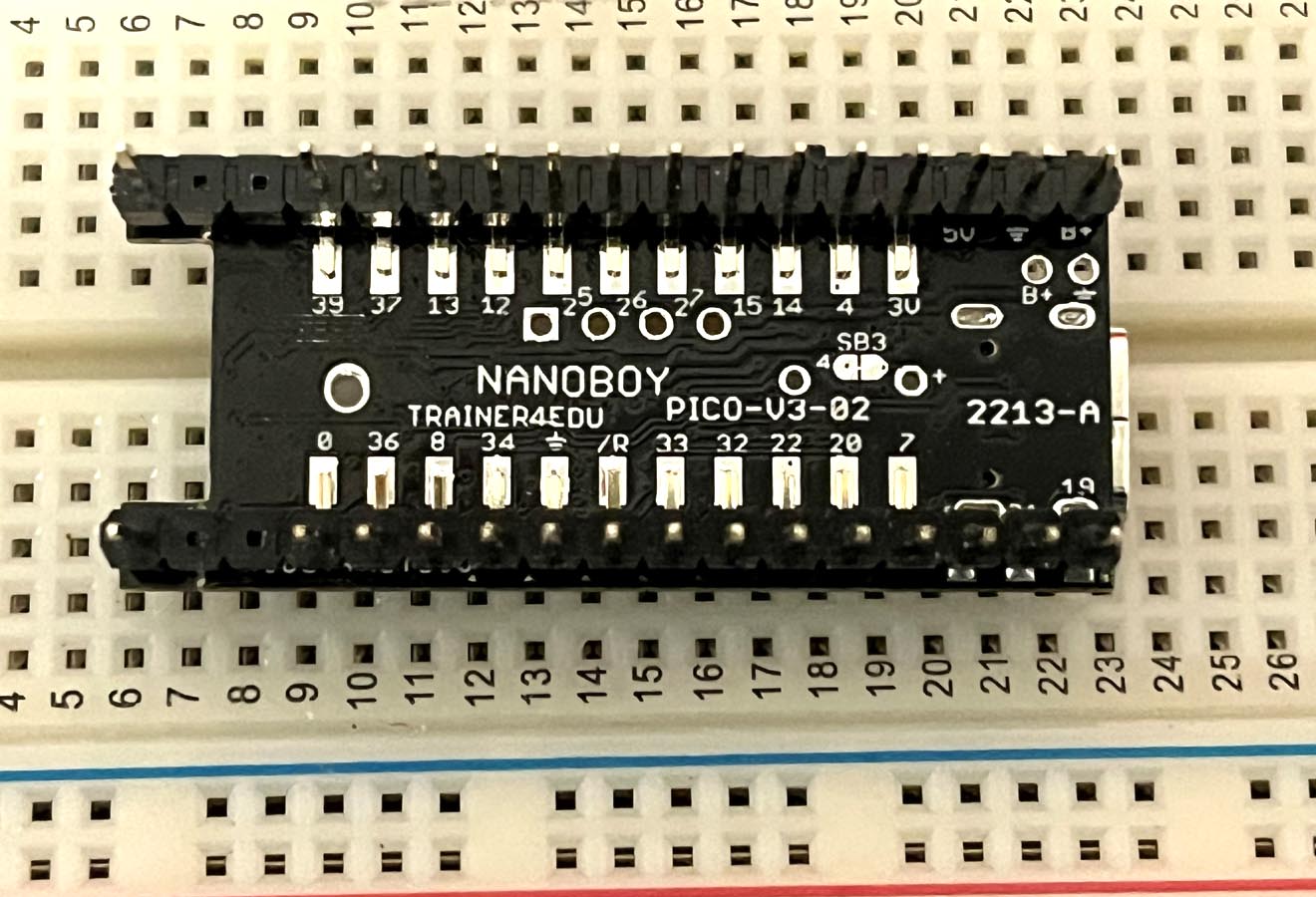

4. Place the 2 modified male headers on a

breadboard 0.6" apart as shown on the picture.

|

|

|

|

|

|

|

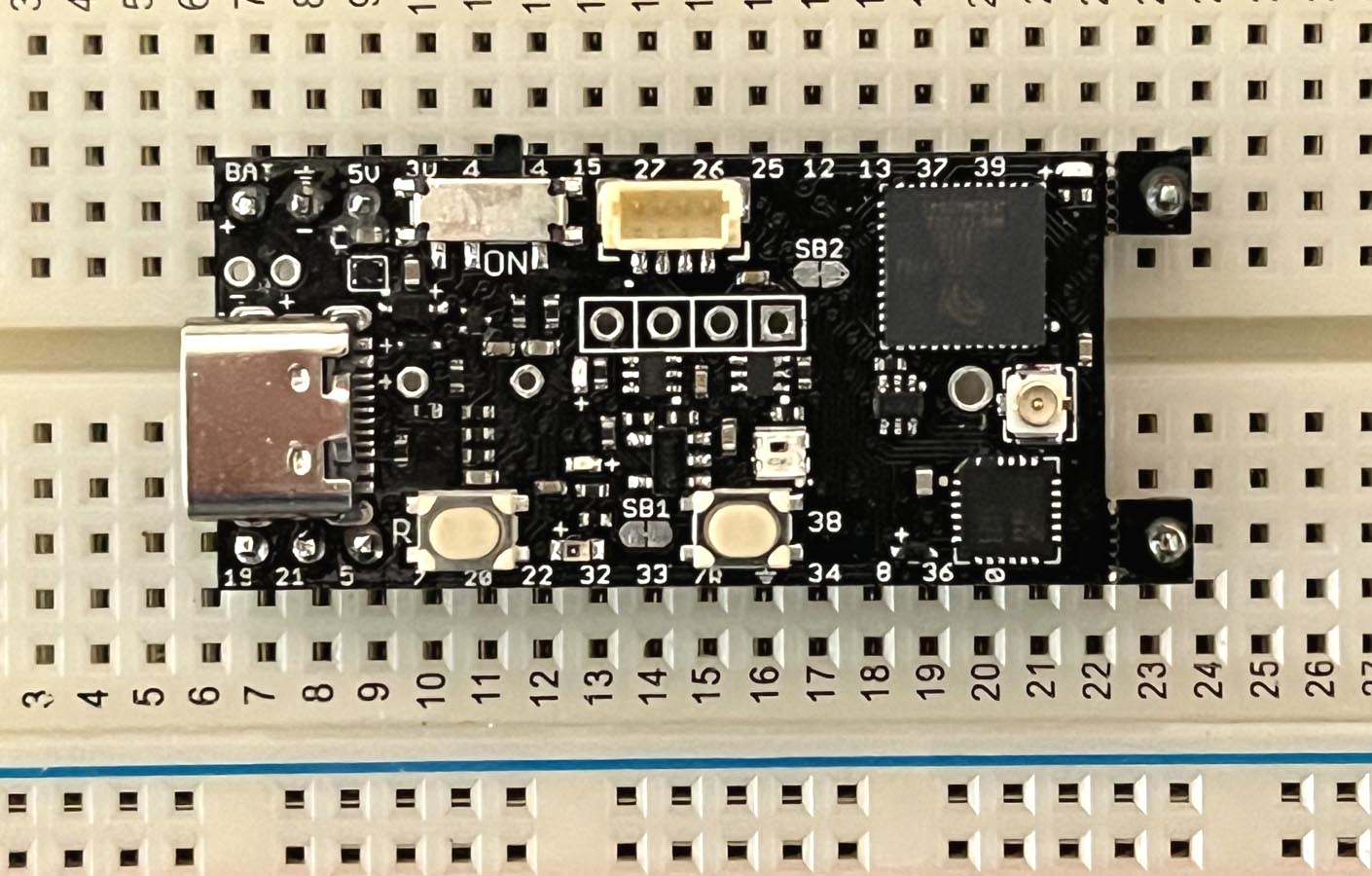

5. Place the NanoboyPICO board over the headers.

Press it down and make sure the board is

leveled.

Solder 4 corner pins first. When

soldering the first corner pin, press down the board

at the middle so the board will be leveled

even you apply pressure on a corner pin during

soldering. After soldering the 1st corner pin

make sure the board is leveled. Check it as

shown on the next picture.

Finally solder all other remaining pins. |

|

|

|

|

|

|

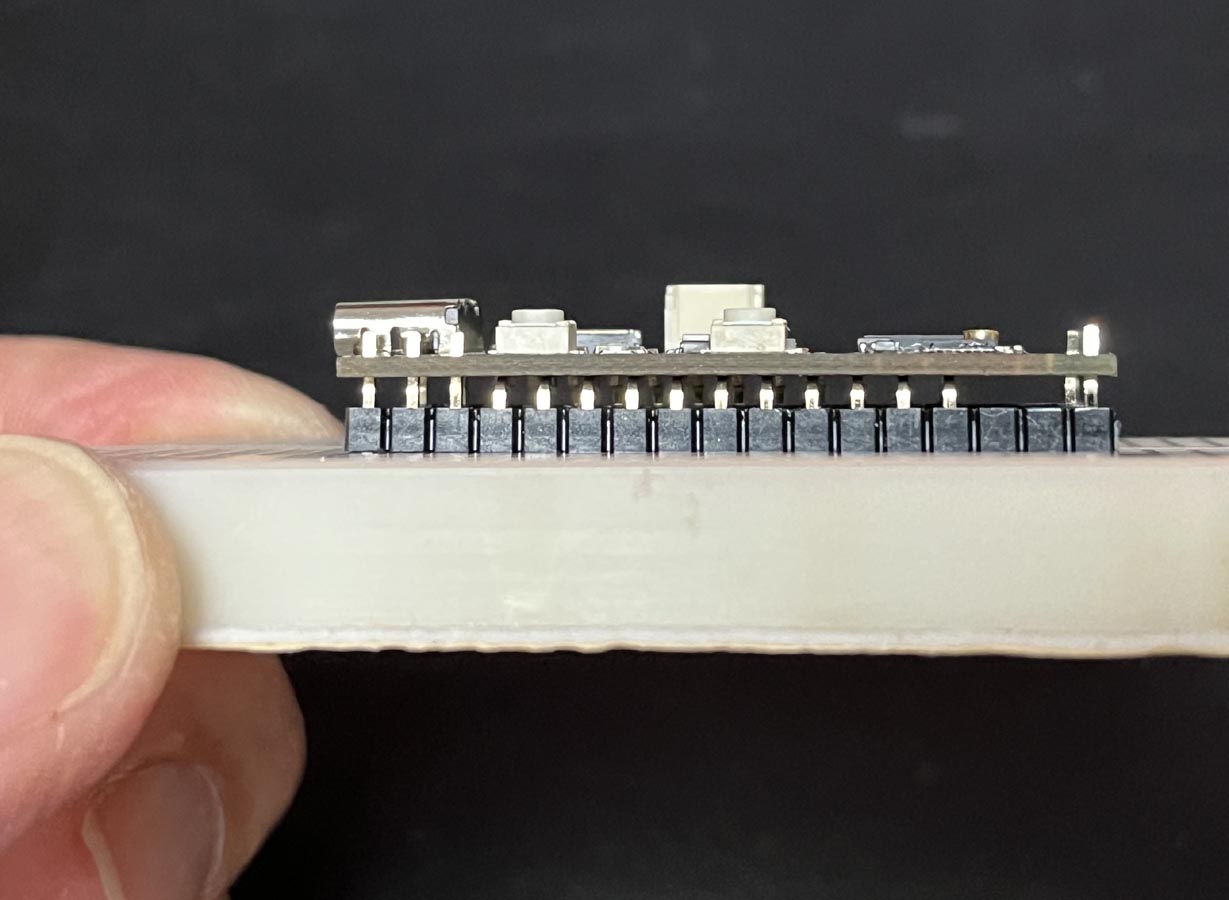

6. After soldering all pins on the top you

should see the side view of the board like this. |

|

|

|

|

|

|

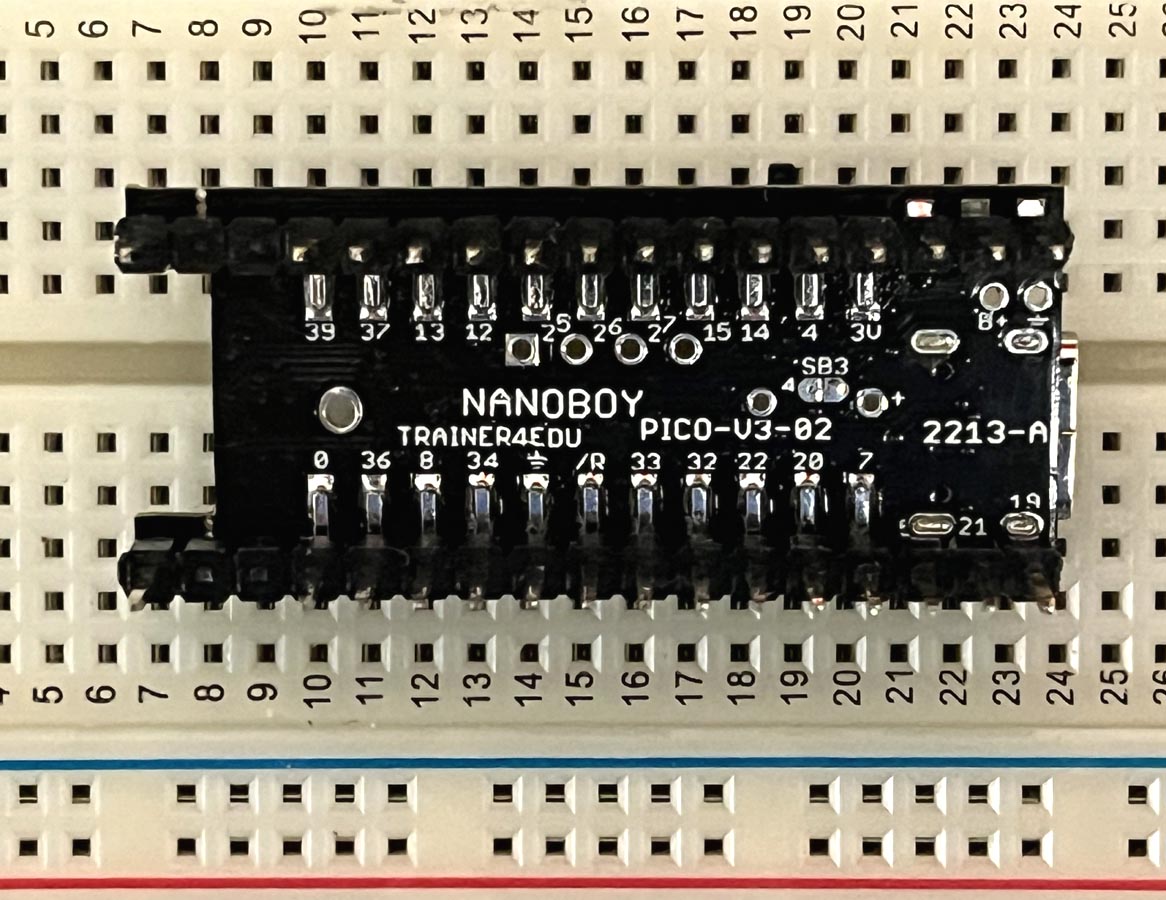

7. Take out the board from the breadboard and

flip it over.

Add a lot of solder flux on all remaining pins at the

bottom, then solder every pin. |

|

|

|

|

|

|

8. All pins at the bottom are soldered and water

soluble flux residual is cleaned up.

In the recent 30 years I use water-soluble flux only. because it's

much easier for soldering. The solder

joint is also very shining. For production

quantity I can wash

away the flux residual with a dish washer. For

small prototypes

I just brush some

water to clean the spot. After that I will

shake off the water and use napkin to wipe

water away. Make sure use a heat gun or a hair

dryer to dry the board if you need to test it

immediately.

If you use non-clean flux, you need to use 90%

Isopropyl Alcohol to clean up solder residual. |

|

|

|

|

|

|

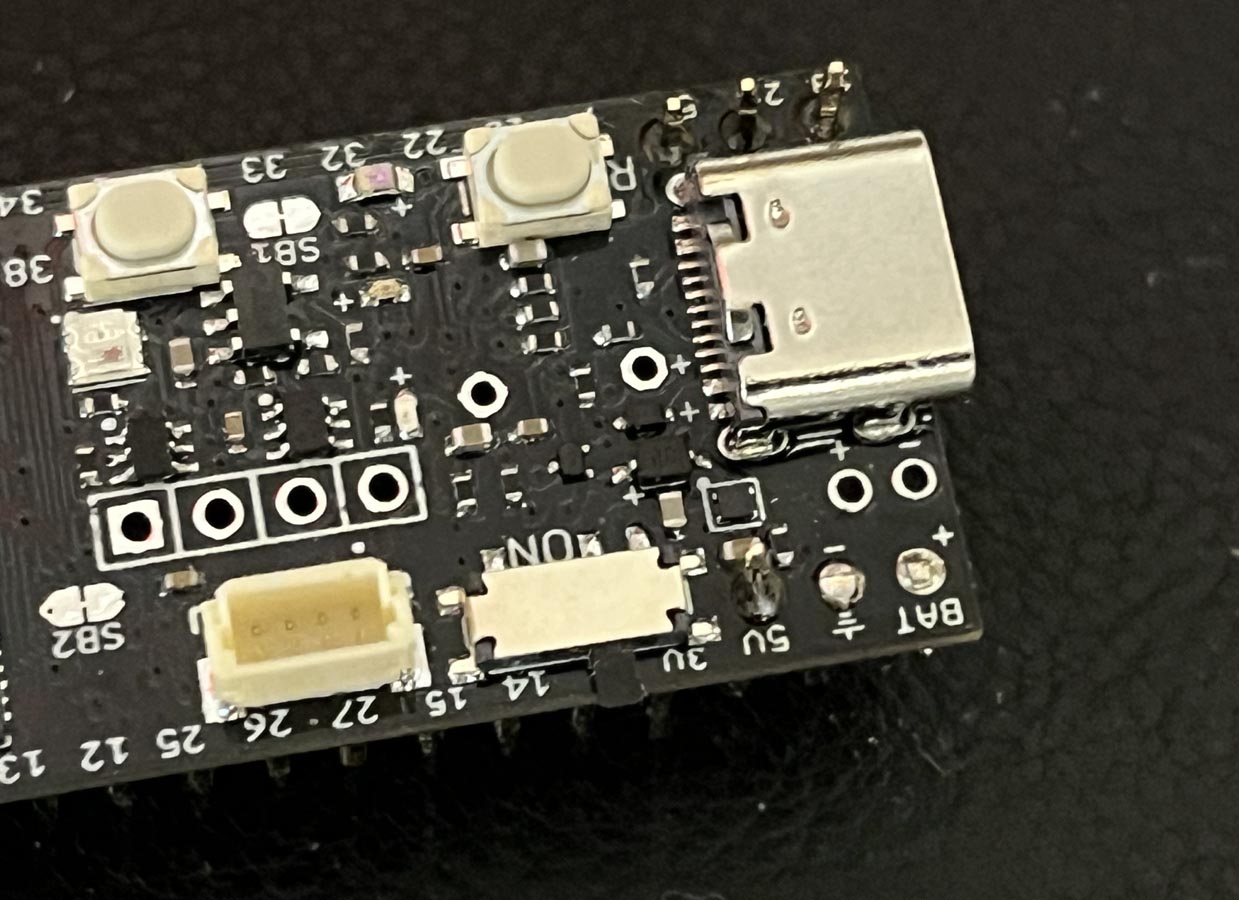

9. Flush cut two battery connector pins at the top. Use

90% Isopropyl Alcohol to remove solder residual of

non-clean flux or just water to remove solder

residual of water soluble flux.

Then solder the JST connector. After soldering one pin check if the connector

is perfectly in the horizontal position. If not,

you can adjust it when heating the pin. When the connector is perfectly in the horizontal

position, then solder the other pin .

|

|

|

|

|

|

|

10. Cut the helper-pins away and break off 2

small pieces of the PCB.

Then break off the

extra plastic body on the male headers.

See the video clip

|

|

|

|

|

|

|

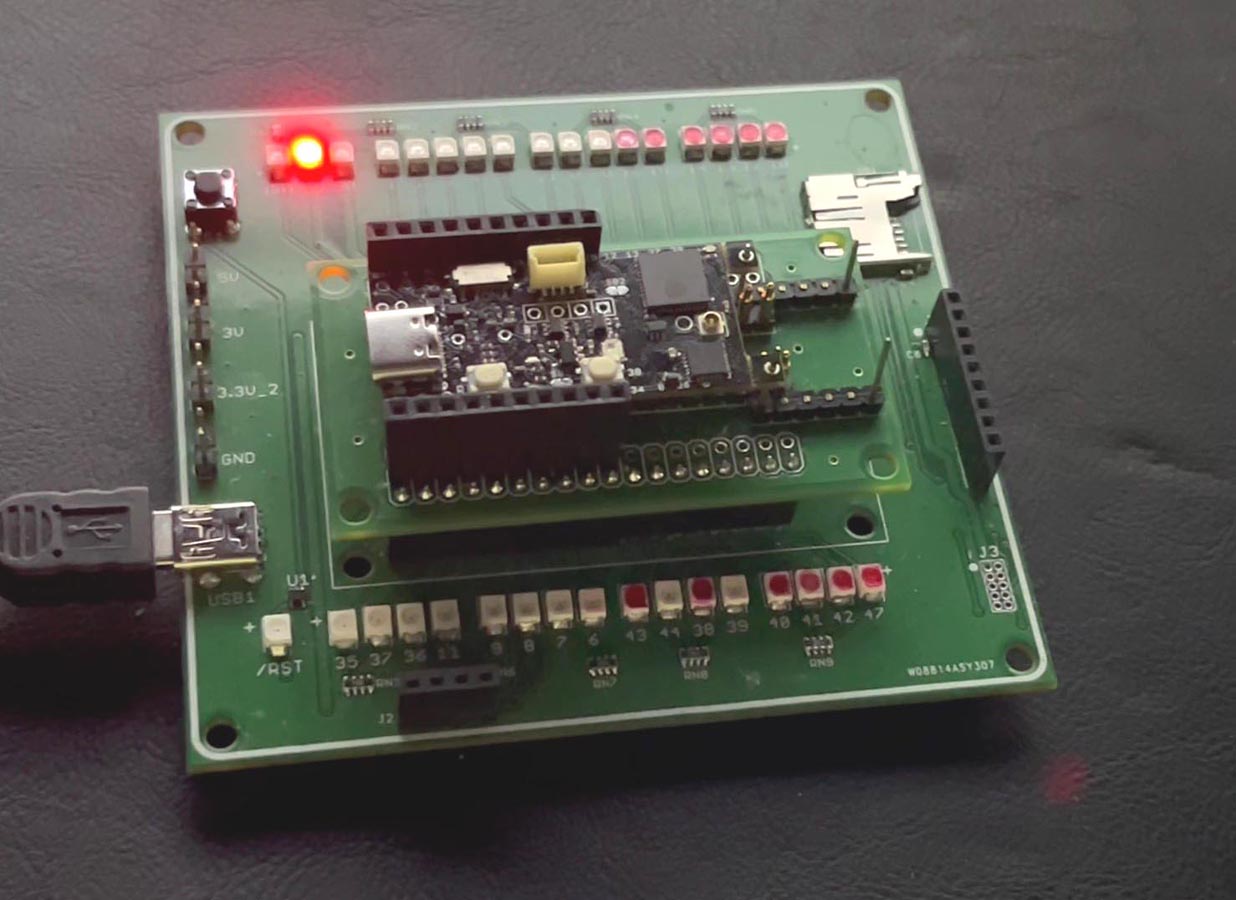

11. This is the final assembled board.

Take care of the LiPo battery connector. When you need to unplug a battery cable hold the

connector with one hand and unplug the cable

with the other hand.

Since the board has a power switch, you can

turn off the switch instead of unplugging the battery cable and

USB cable. The power switch only

disconnect the power to the LDO. So it

disconnects the battery but not the USB 5V. The 5V LED will

still be ON as long as the USB is plugged in,

but the current from a USB hub is very insignificant

when the power switch is in OFF position. |

|

|

|

|

|

|

12. If you want to play the Flappy Bird

game, you need to solder an active buzzer and a

0.96" OLED.

Most DIY makers probably already have a 0.96" OLED

display. |

|

|

|

|

|

|

13. Cut off the tab on a battery cable

connector.

Sometimes the the battery connector is too tight

and hard to pull the cable out. You can cut off

the tab in the middle, otherwise you may pull

out the connector from the PCB.

|

|

|

|

|

|

|

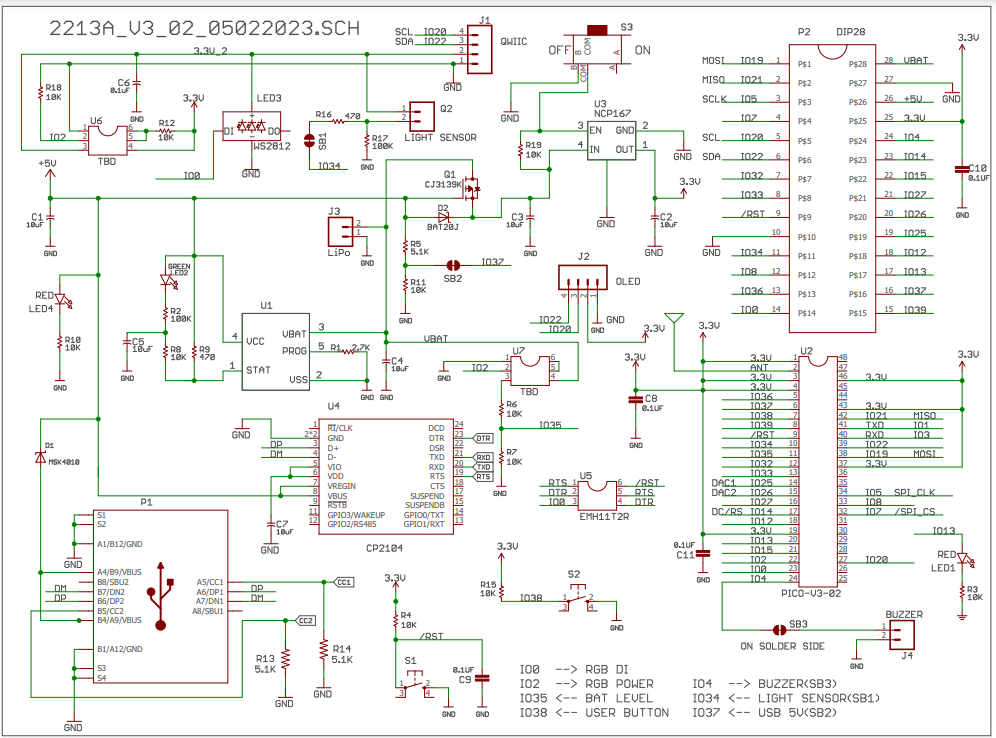

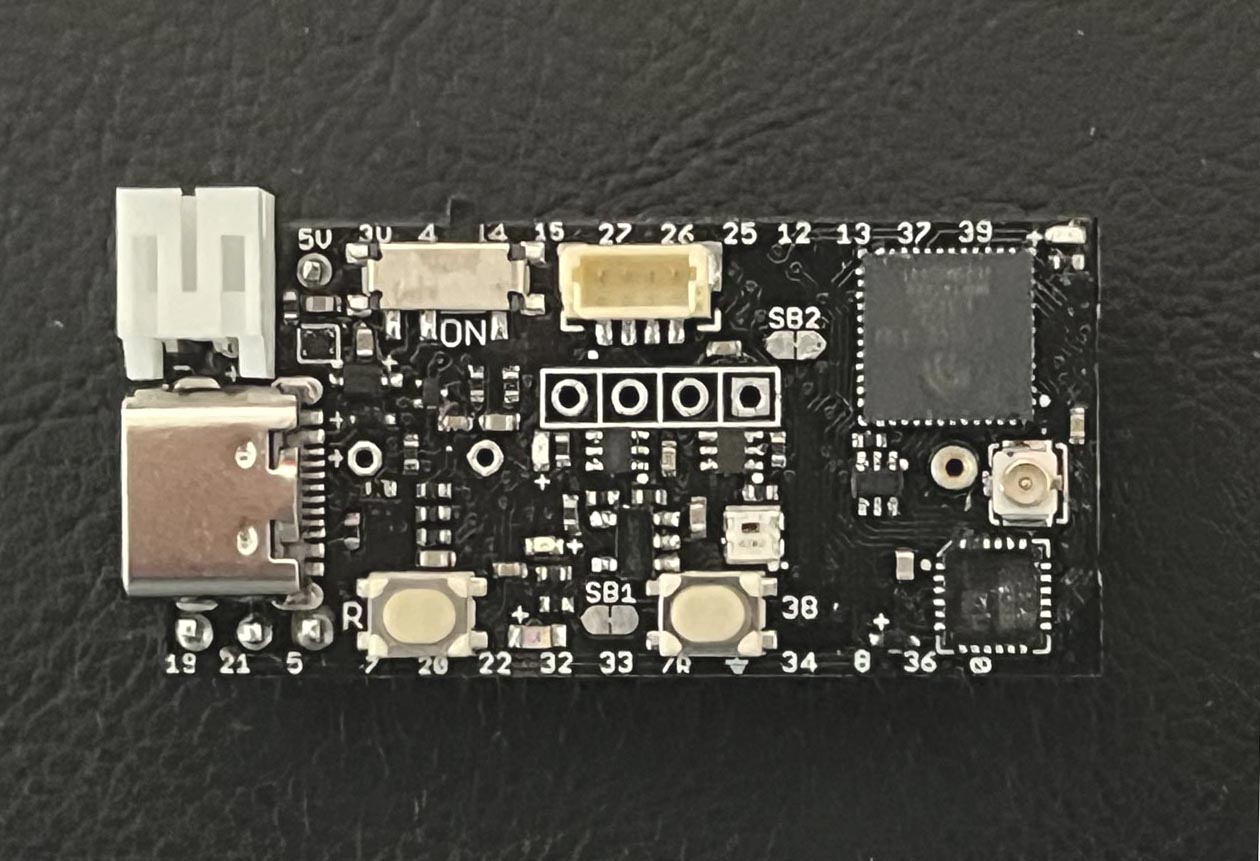

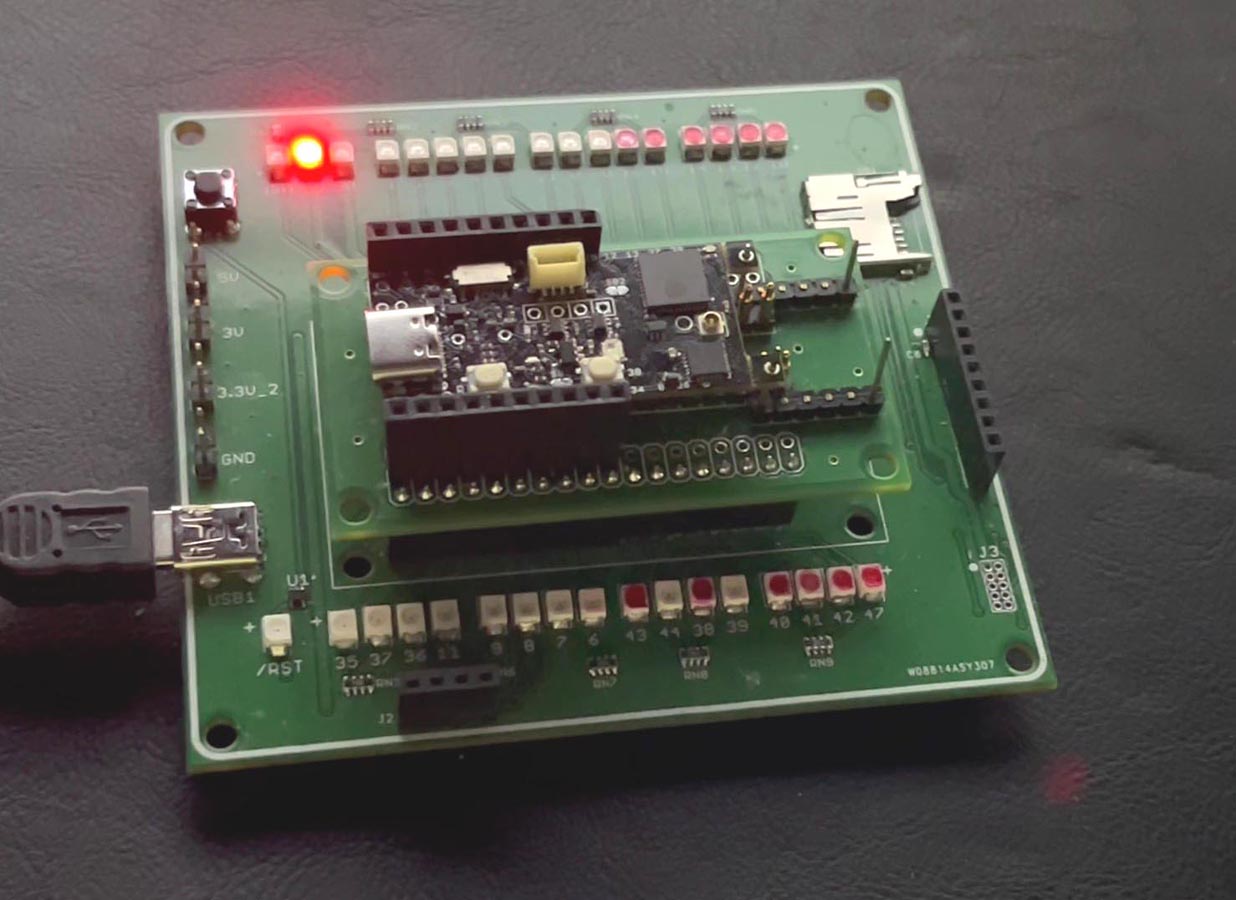

A makeshift test jig (for both NanoboyPICO-V3-02

and NanoboyS3)

The NanoboyPICO-V3-02 is preloaded with a test sketch

that will flash all output pins.

After you receive it, you should try to upload

the Blink-A-LED example sketch before soldering all male

pins. |

Trainer4Edu.com

SmallPICO.com

Nanoboy.com

Flappy Bird

Trainer4Edu.com

SmallPICO.com

Nanoboy.com

Flappy Bird