| |

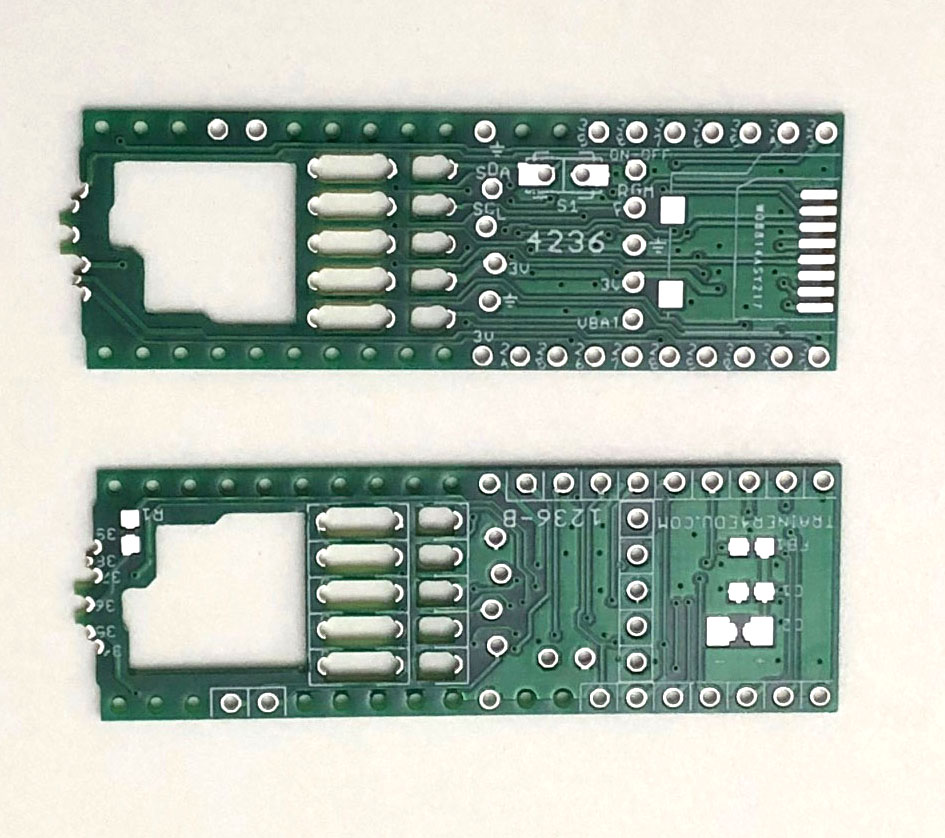

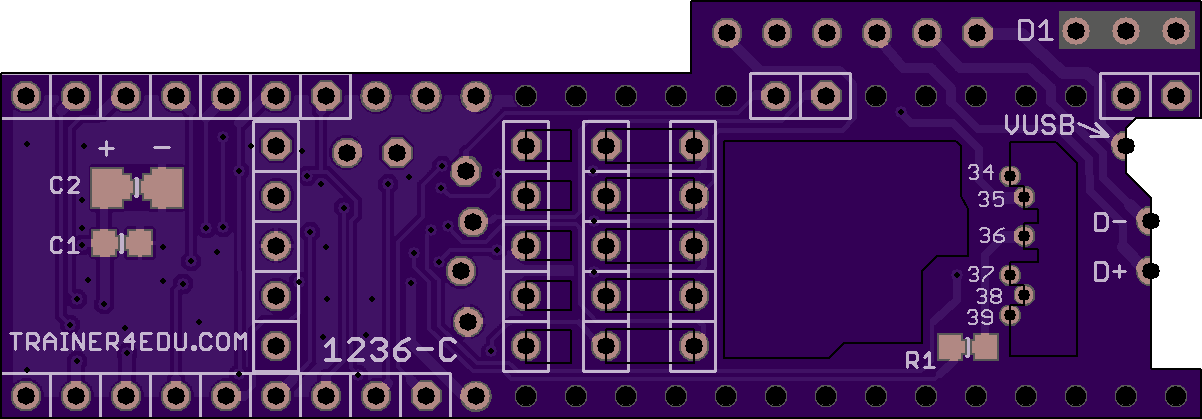

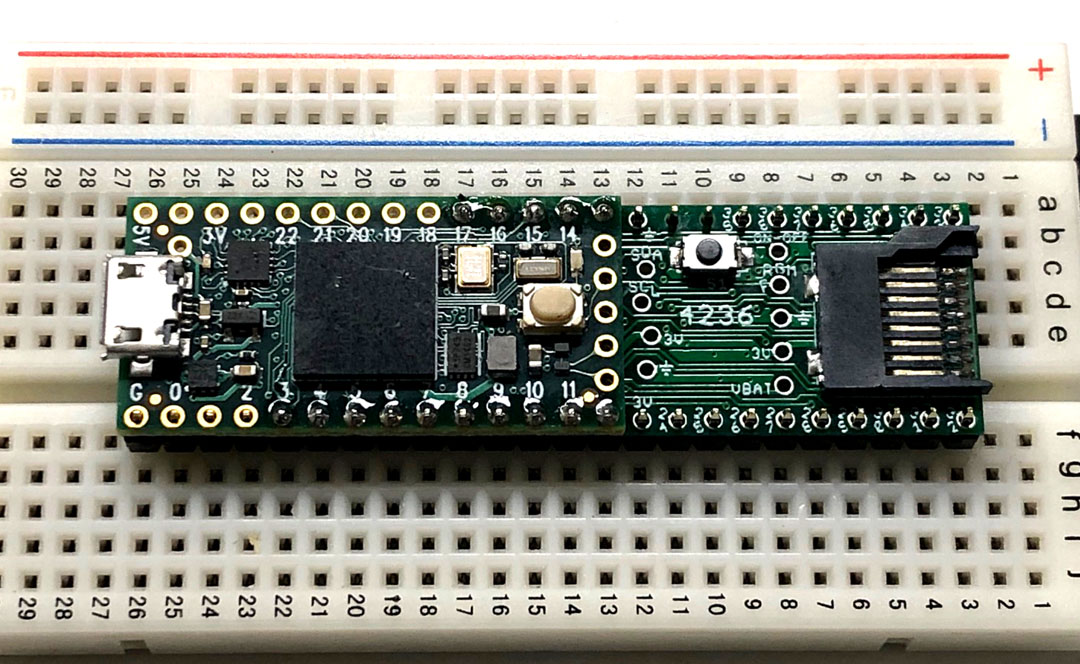

FRDM4236 features:

1.

Staggered castellation for 1mm pitch holes, the

staggered

castellation holes are a bit larger and easier to be

soldered without creating a solder bridge to an adjacent

hole/pad.

2.

Built-in SD card. When SD is not used, the D34-D39

can be used as I/O pins.

3.

All components can be 0805, except C2 can even be 1206,

easier for DIY.

4.

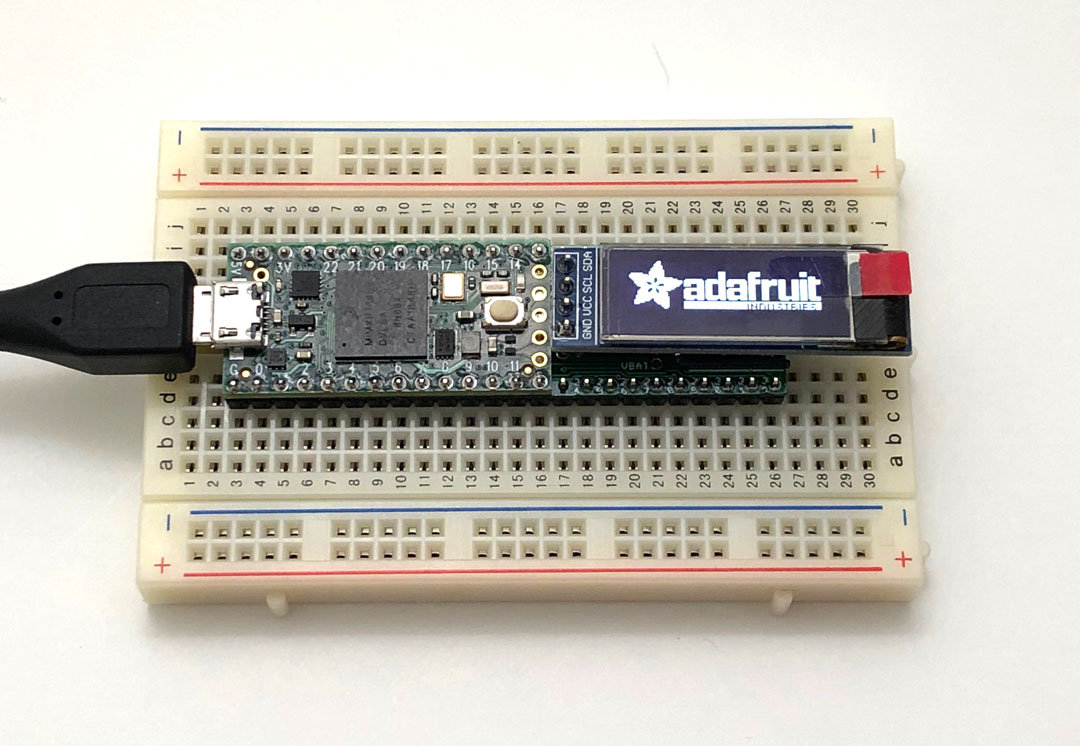

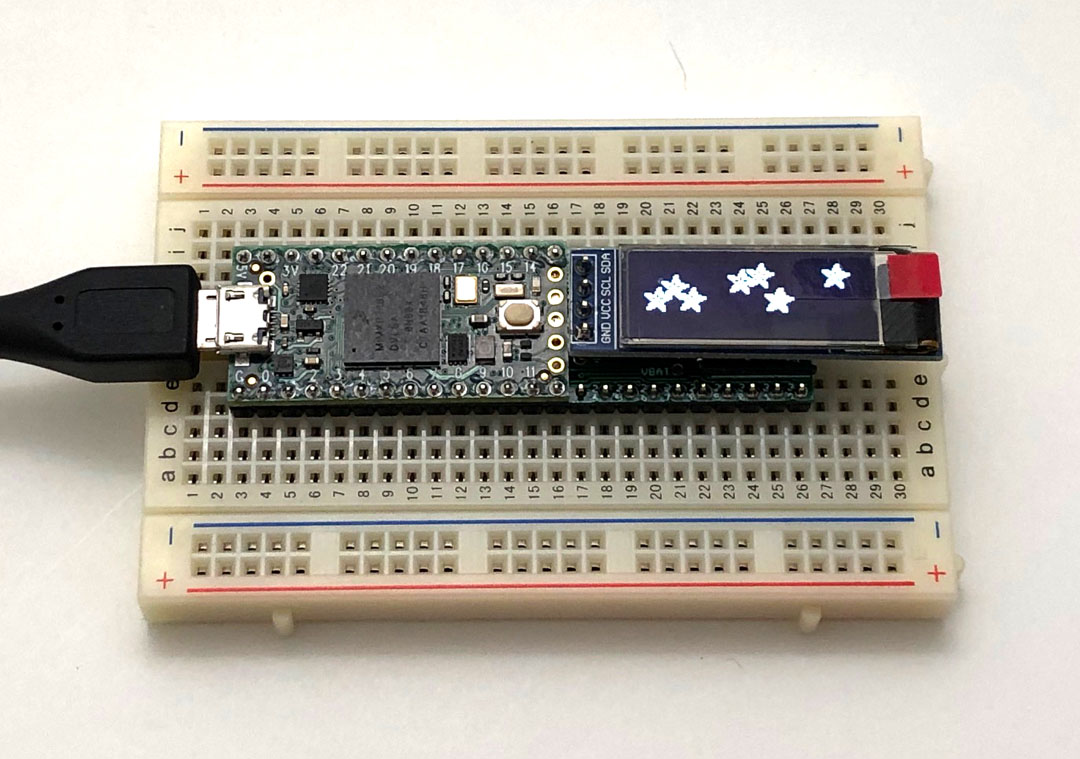

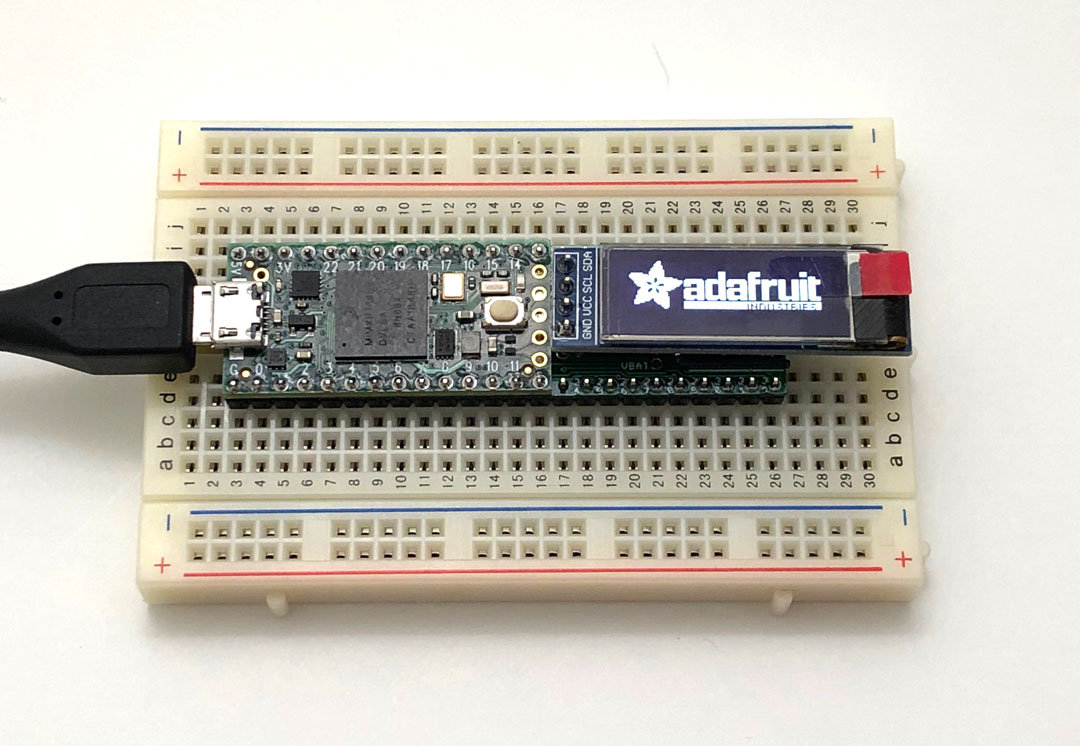

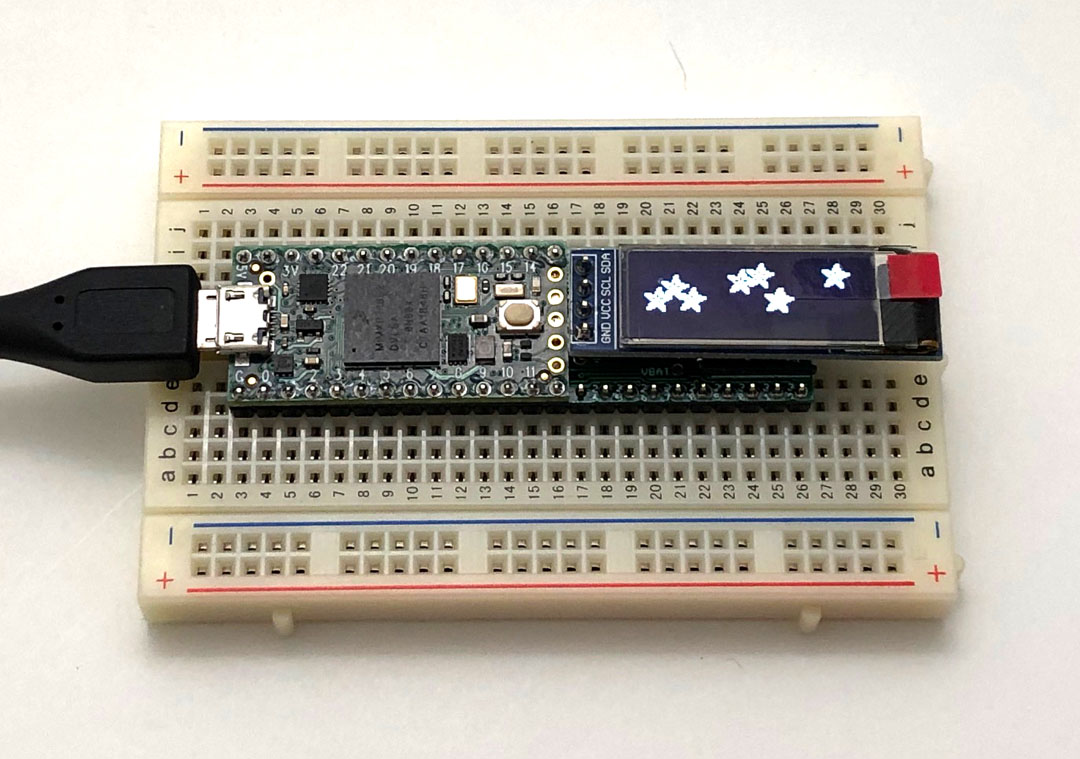

Self-locking pads for a 128x32 OLED display.

5.

Teensy 3.6 footprint and breadboard friendly.

6.

Low cost, PCB and all parts including two 24x1 male

headers should be < $5.

Soldering instructions:

Because this breakout board has 1mm pitch castellated

holes, you need to prevent no-clean flux residue trapped

around the 1mm pitch holes, especially the final product

is made of 2 stacking boards. So if you use non-clean

flux, use as little as possible.

After soldering, flux residue could be conductive

especially if board is contaminated.

|

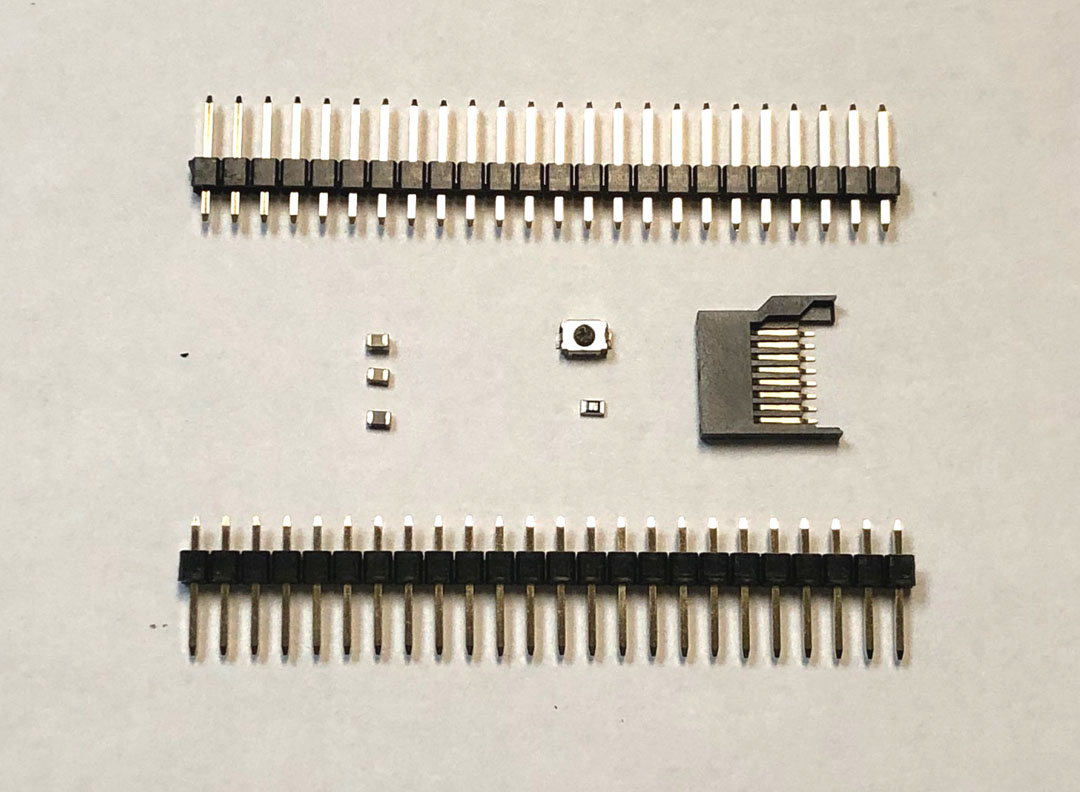

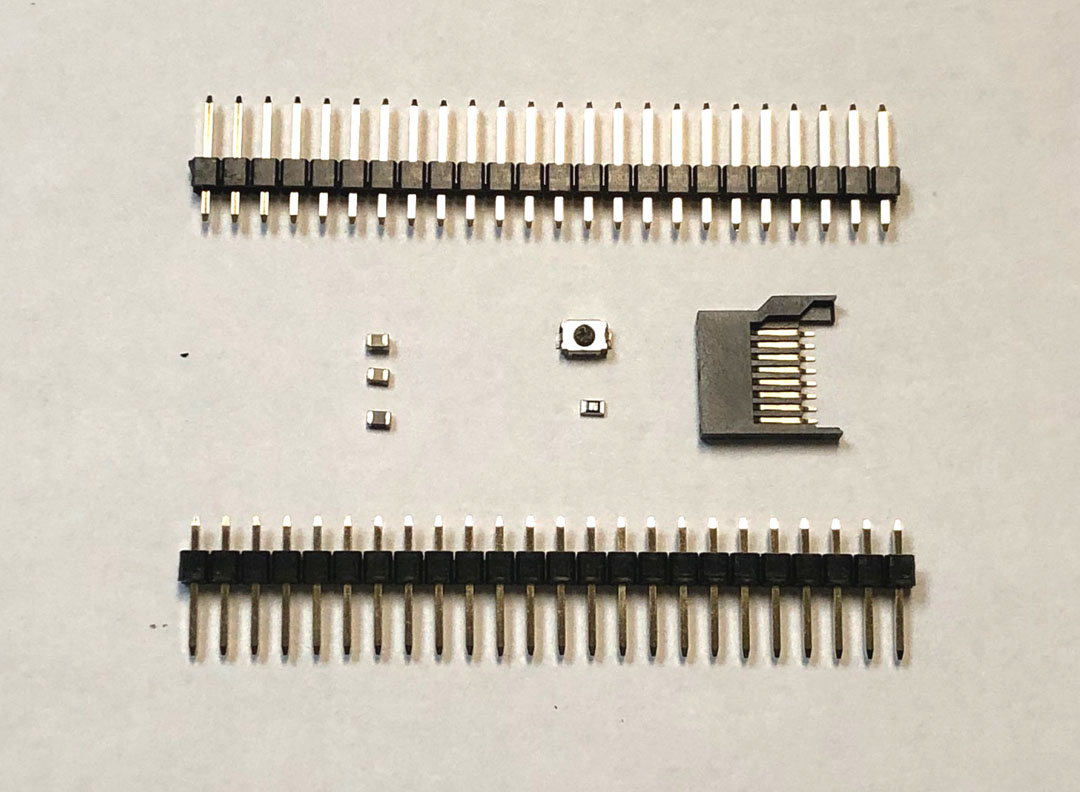

1. These are the parts you need:

-

FB1:

120-150 ohm Ferrite Bead, 0402-0805 (This

part is omitted on the new board)

-

C1: 0.1UF,

0402-0805

-

C2: 10-47UF,

0402-1206

-

R1: 22 ohm,

0402-0805

-

S1:

Pushbutton Switch

-

J1: 24x1

male header, 0.1" pitch

-

J2: 24x1

male header, 0.1" pitch

-

SD1: Micro SD card

slot

|

|

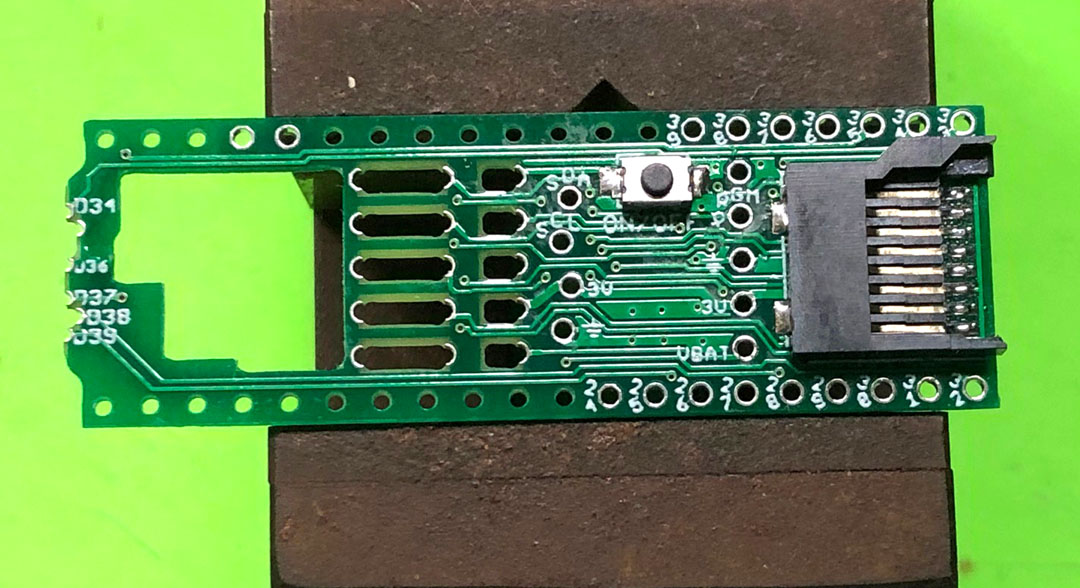

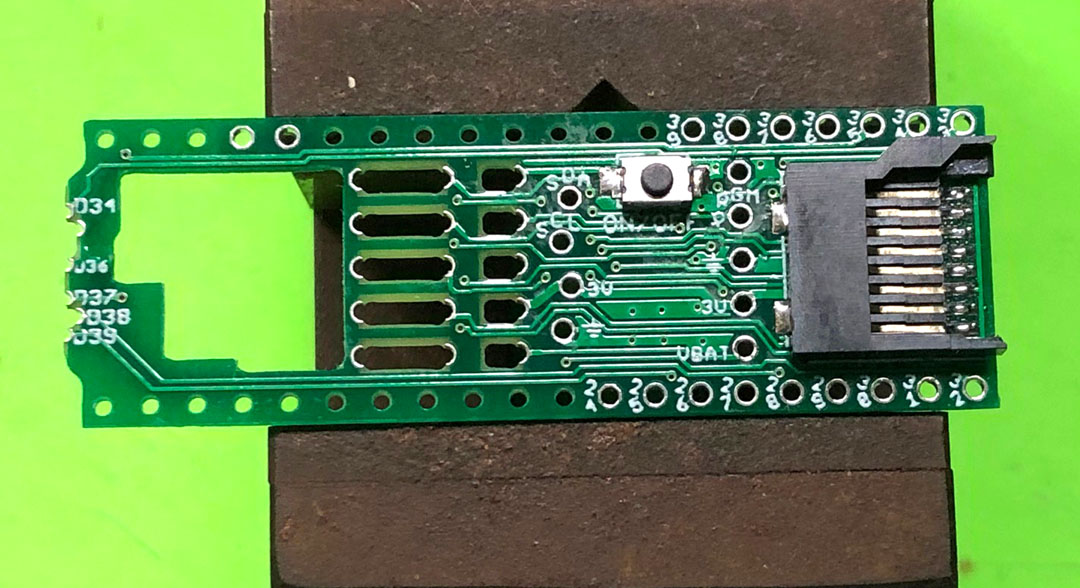

2. Solder all components, FB1, C1, C2, R1, S1,

SD1, on the breakout board. After soldering, If

you use water soluble flux, you can wash it with

soap, brush it with a tooth brush, rinse it

thoroughly and dry it using a heat gun or a hair

dryer. |

|

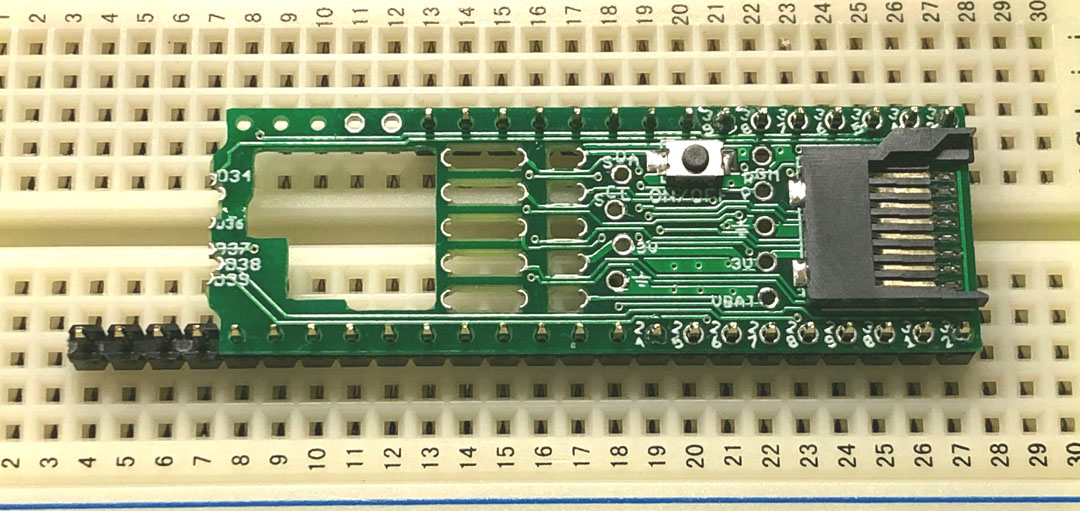

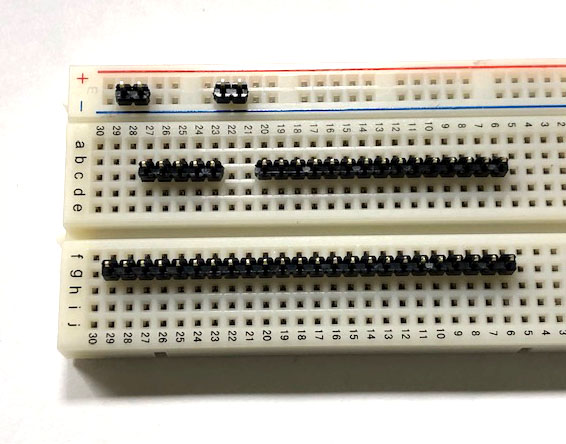

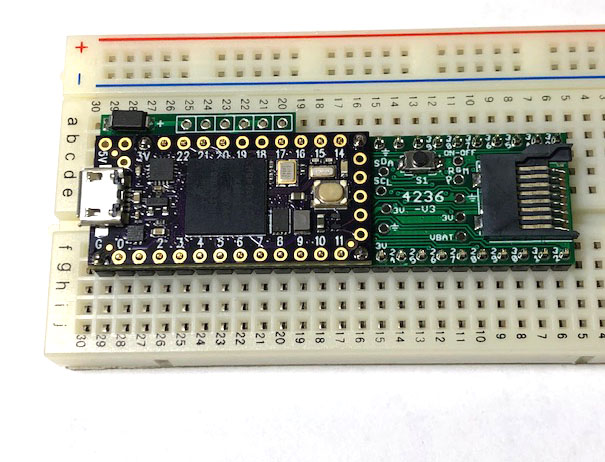

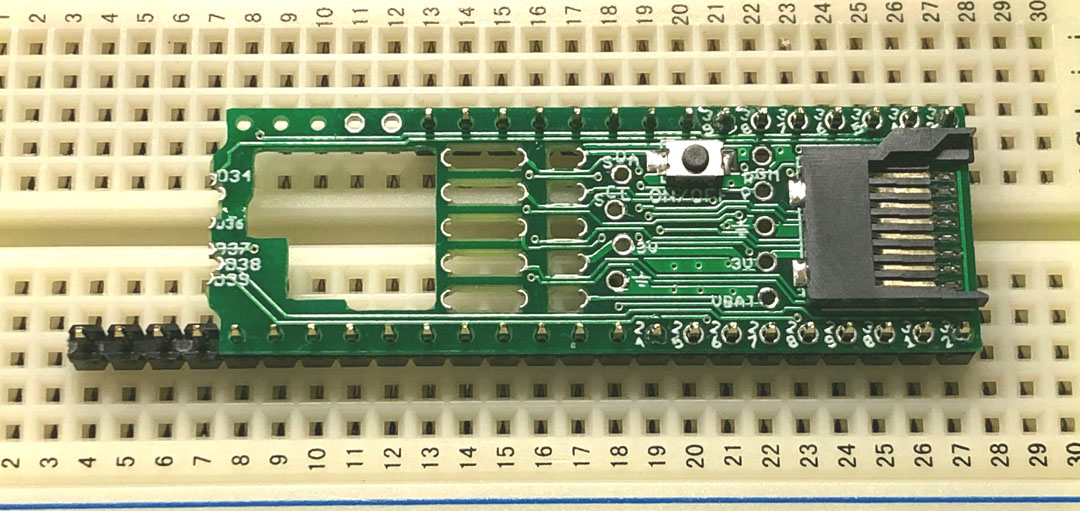

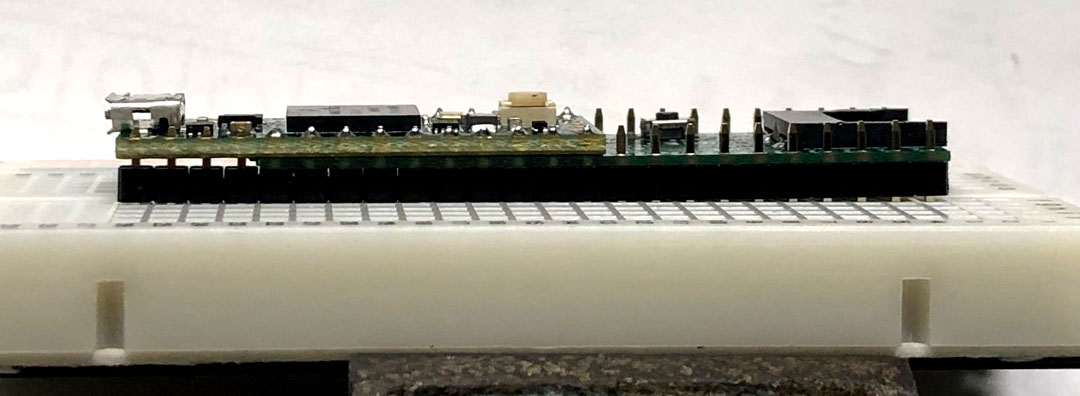

3. Break J2 into 3 pieces, 7x1, 2x1 and

15x1. Place J1 and 15x1 headers on a

breadboard as shown at left. Make sure that the

headers are 0.6" apart. Do not need 2x1 and

7x1 headers for the time being.

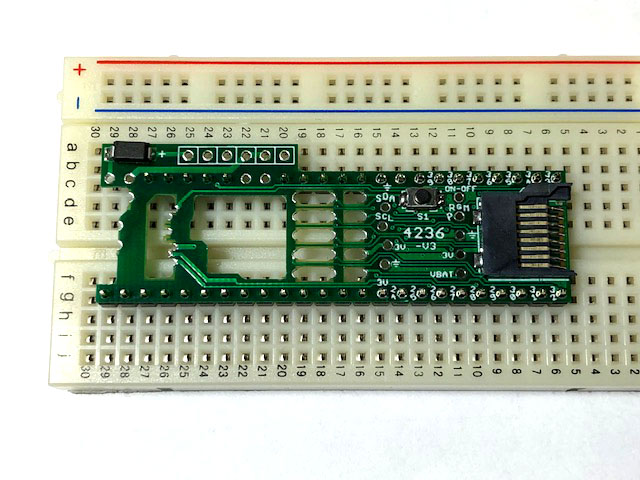

Place the FRDM4236 over the male headers,

right-aligned. It will leave the 4 left-most

pins of J1 uncovered. This is

important. If you misalign it, it will

be difficult to undo after soldering.

|

|

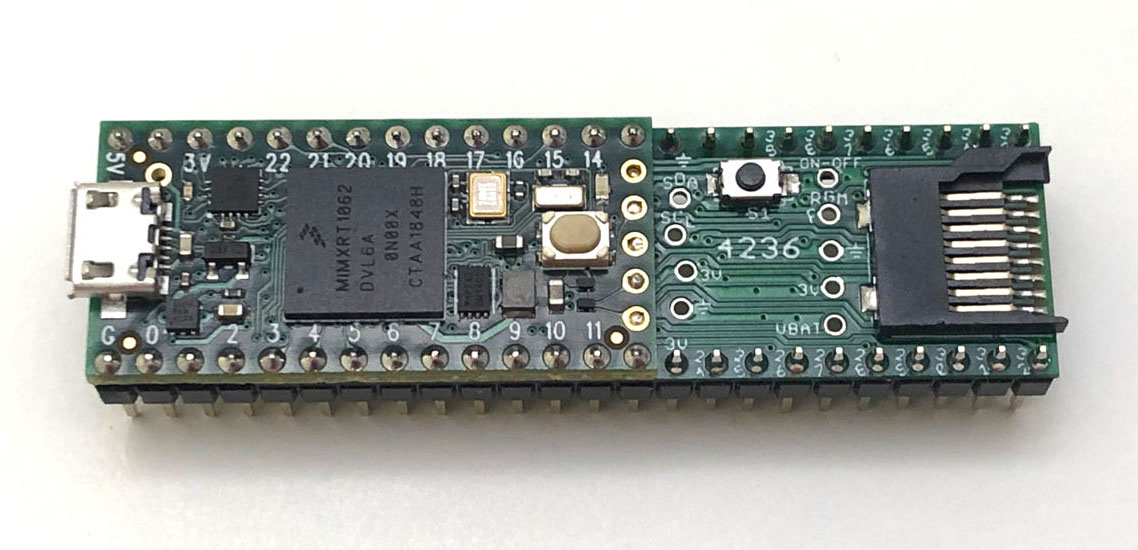

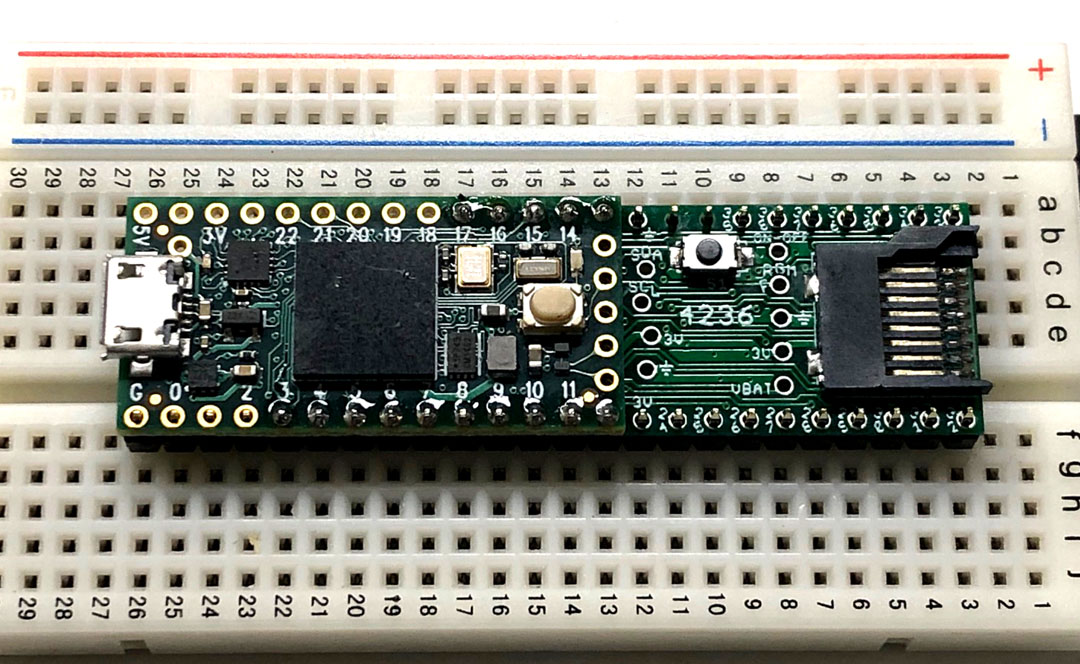

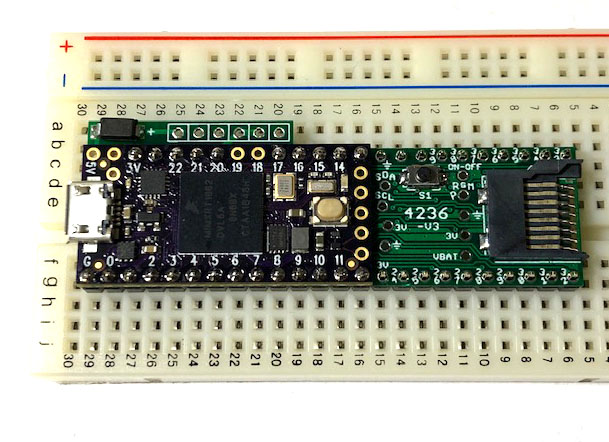

4. Place your Teensy 4 over the breakout board,

left-aligned to the GND pin at low left conner.

Start soldering 4 pins in this order: D3, D13,

D12, D17. Solder pins while pressing down two

boards. |

|

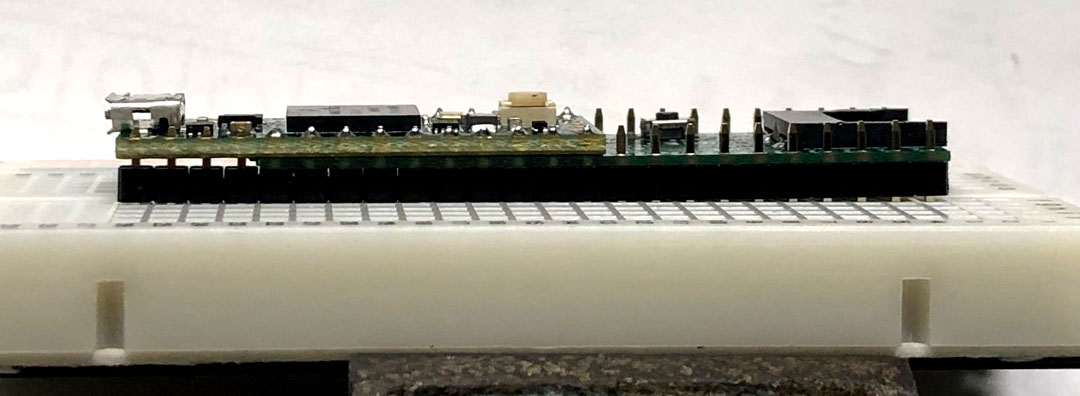

5.

Once those 4 pins are soldered, check to make

sure there is no gap between 2 boards. If there

is, you still have a chance to correct.

Then solder D4-D11, D14-D16 pins, install

7x1 header left-aligned, and solder all 7 pins,

finally solder all other remaining pins.

After that, you only have an opening for a 2x1

header on D18 and D19.

|

|

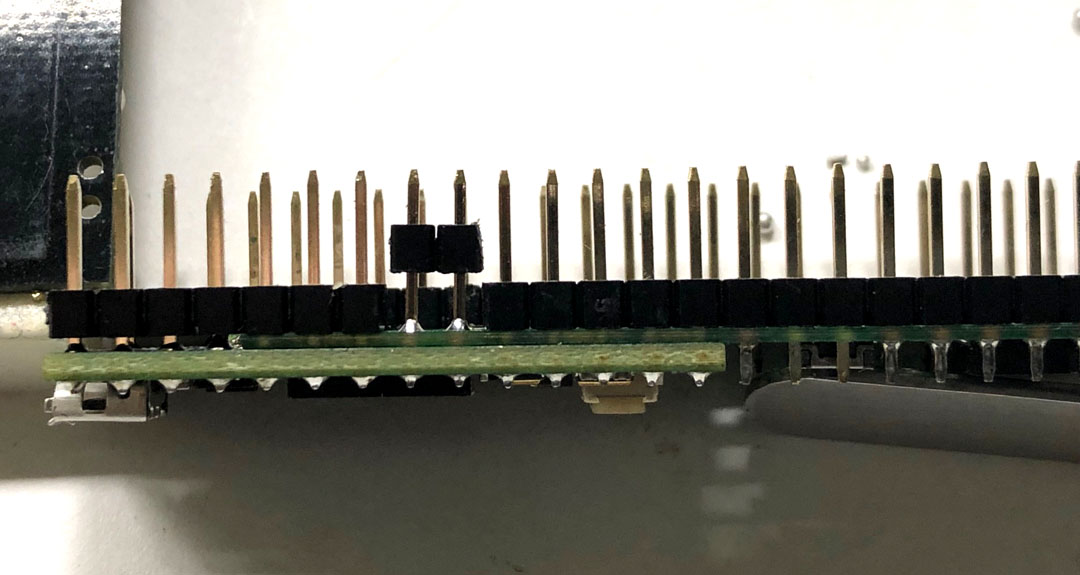

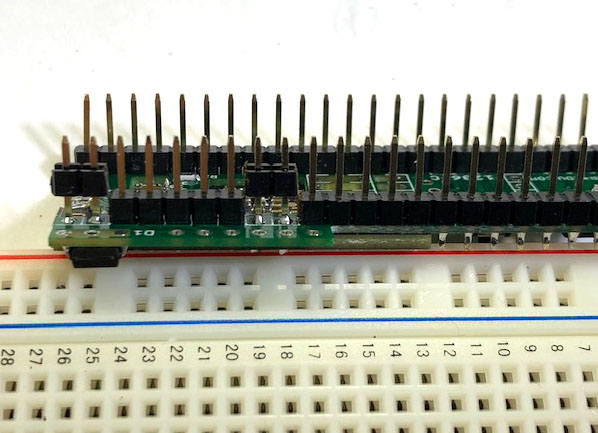

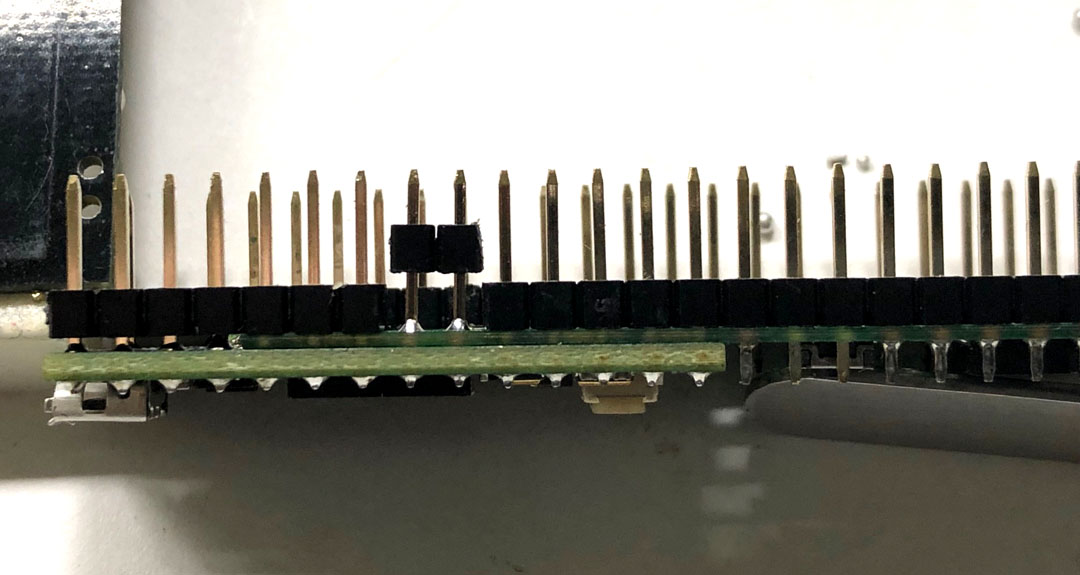

6. Try to fit the 2x1 header into the opening,

you may need to use a small file to make it

narrower, then turn the 2x1 header upside down

and solder the pins to both PCBs. It's easier to place the board on a

breadboard and solder the pins on Teensy 4.0

first, If you heat the pin a little longer, the

solder may flow down to FRDM4236 board. If 2x1

headers are not turned upside down, the plastic

rail of the header may block solder flow, or

solder may not flow down well. The connection

may not be reliable.

Finally push the plastic rail

down. |

|

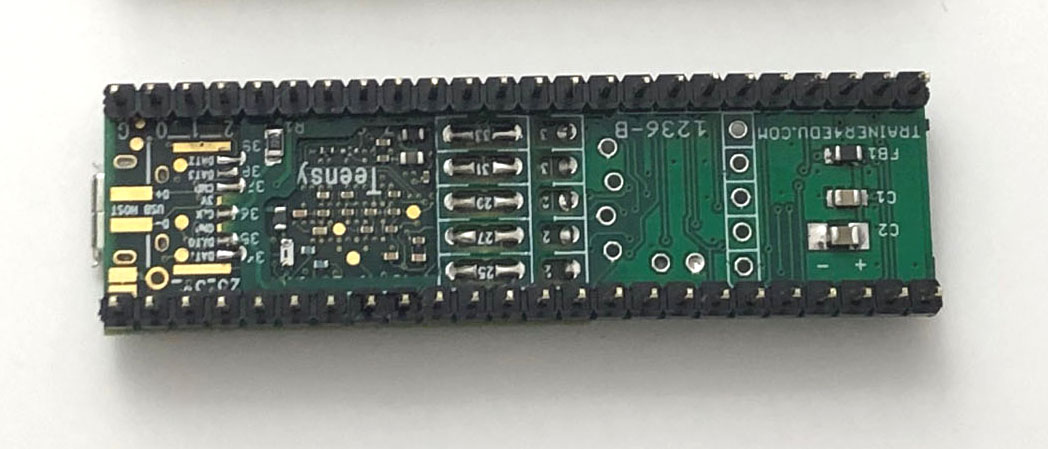

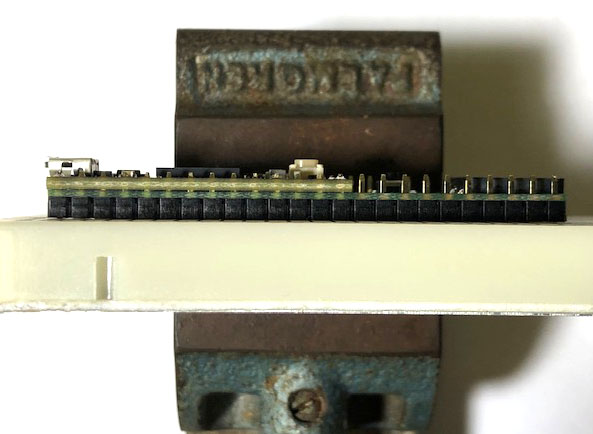

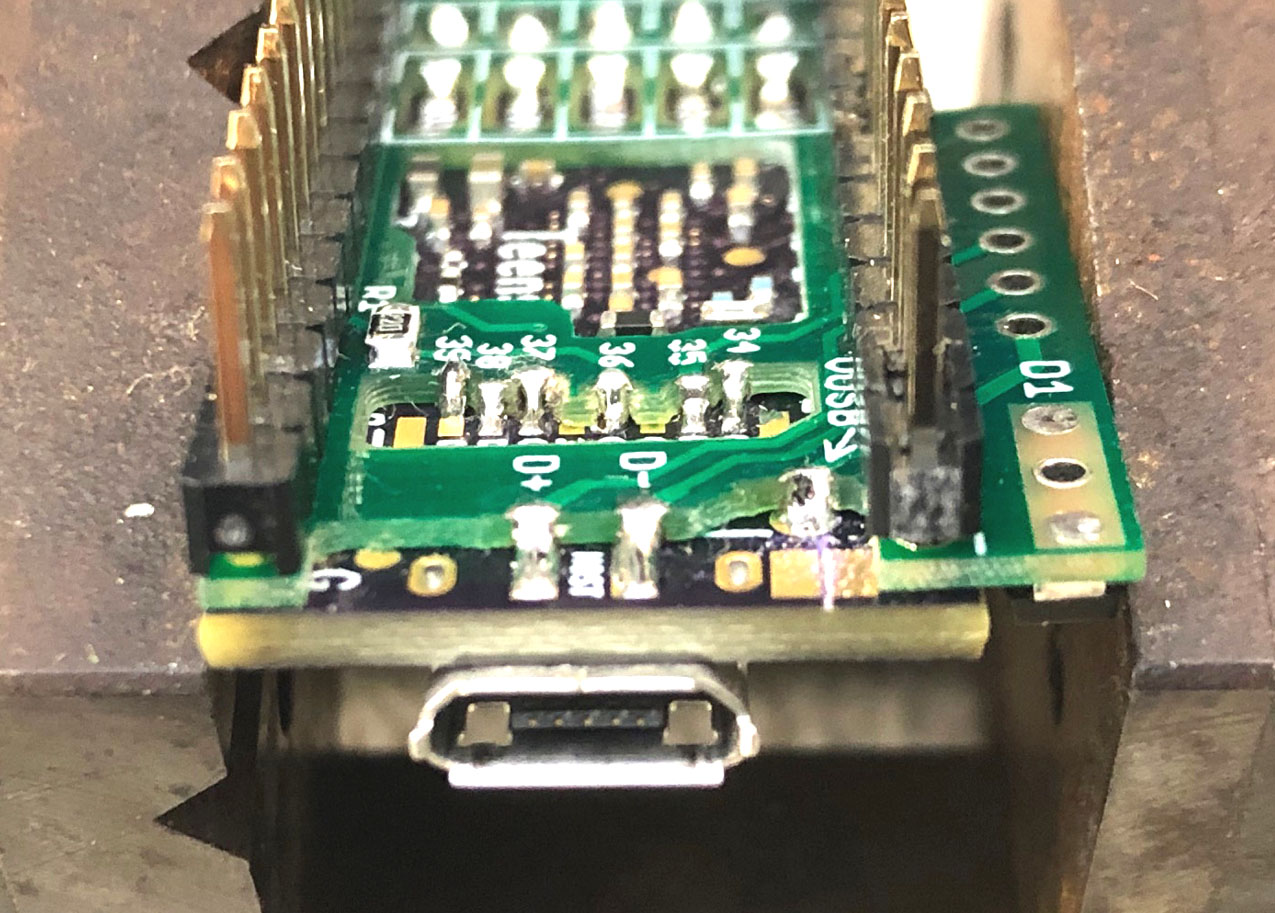

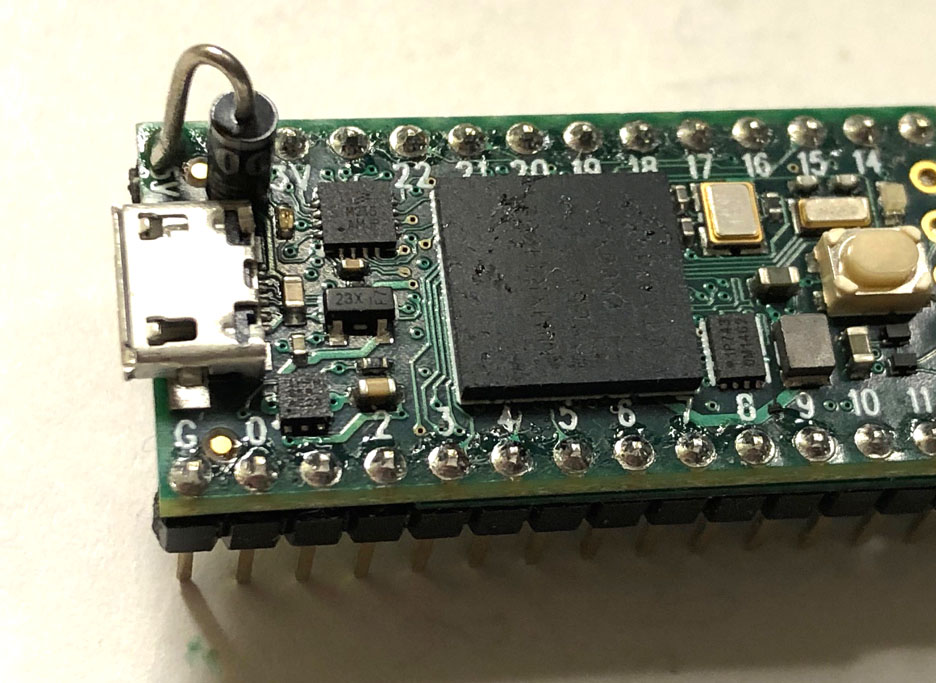

7. It's not difficult to solder all castellated

holes. The 1mm pitch holes need to be soldered

with a small solder iron tip. Keep pressing

the iron tip on pads a little longer and let

solder flow, or you will get cold solder joints. If you use

non-clean flux, use as little as possible.

I just used flux from 0.025" solder wire, did

not add extra. I did not even clean the board

with alcohol. I just used a napkin to wipe

it. If you need to add flux, just apply a

bit on a castellated hole only, do not spread it

out to the adjacent holes. You don't need

to make the solder joints look pretty, as long

as it makes a good connection you can stop.

After soldering you don't want to leave too much

flux residue around 1mm pitch holes and get into

hard to clean spots, it may cause contamination

and residue becomes conductive. When using

alcohol to clean you may spread out residue and

contamination to hard to reach spots since this

is a two stacking board construction.

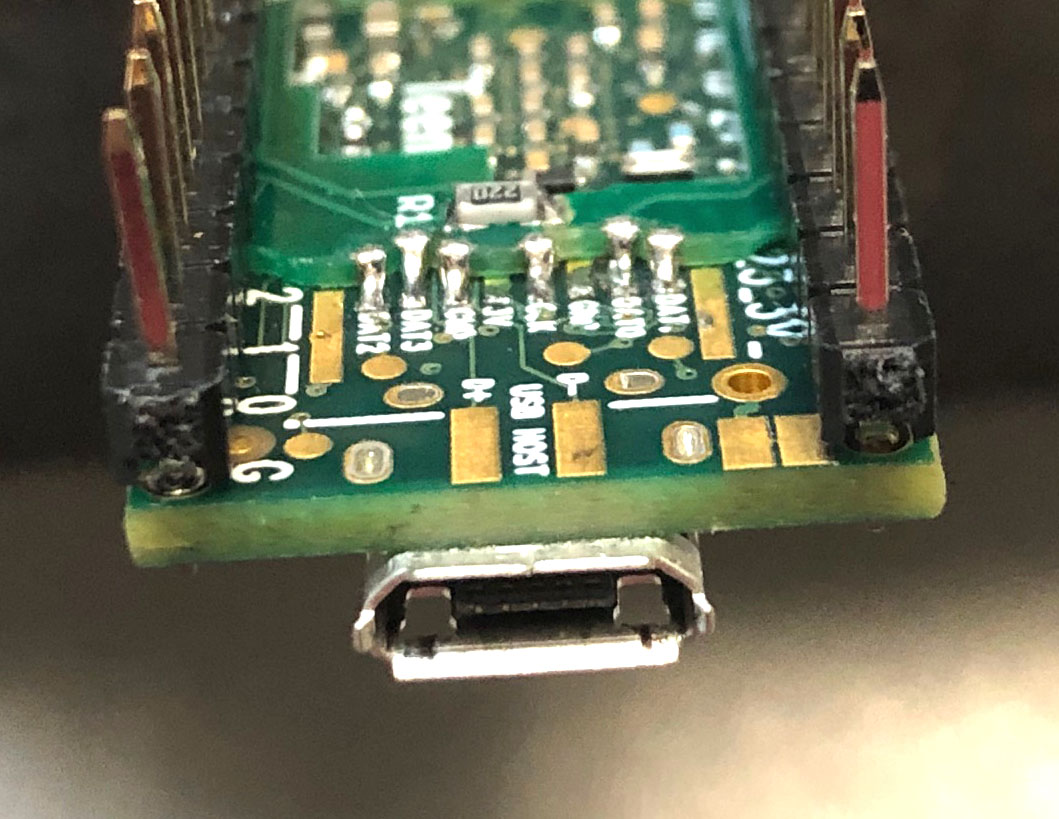

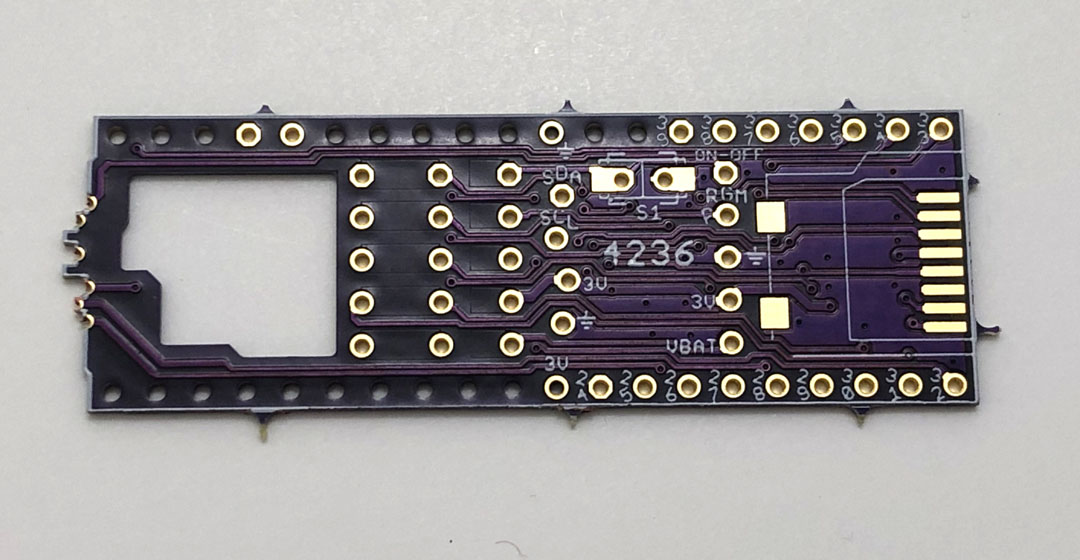

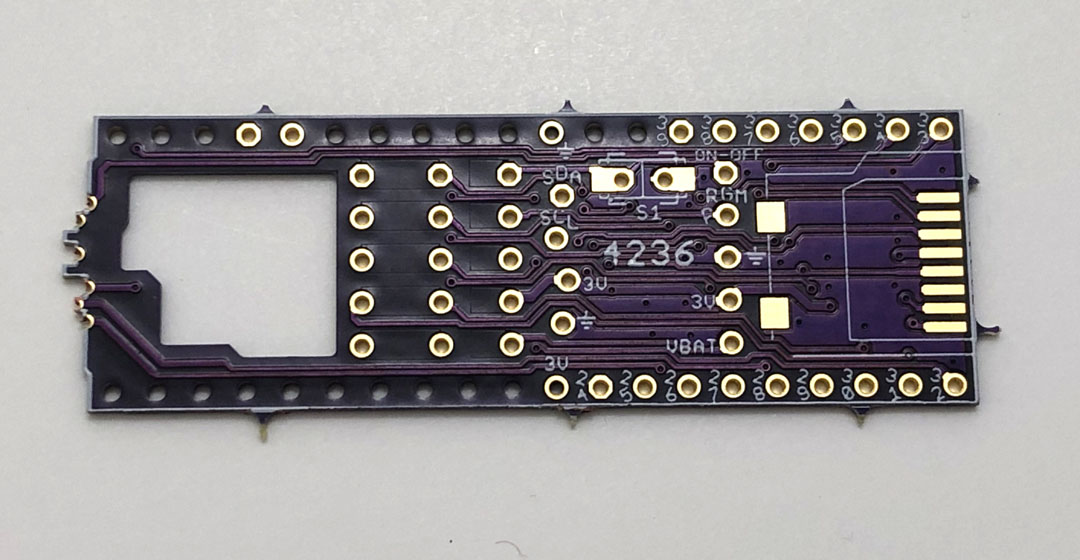

This is the result of soldering with non-clean

flux on rev. A board. |

|

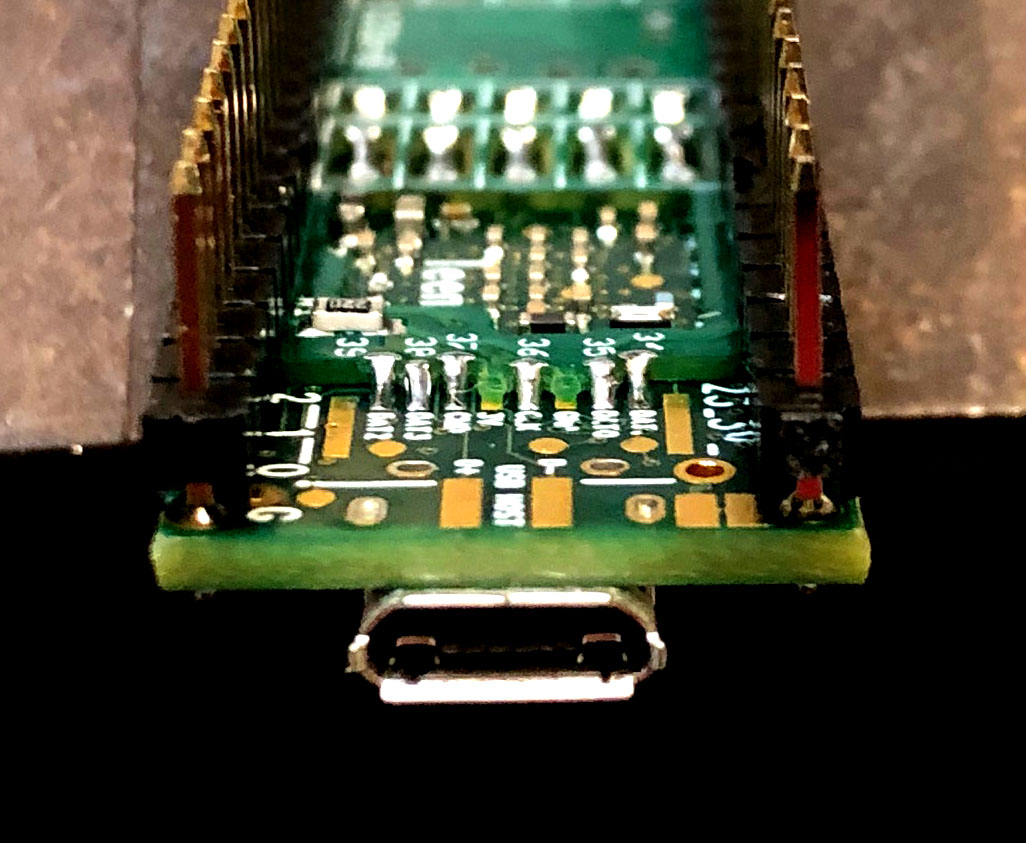

8.

This is the result of soldering with water

soluble flux on rev. B board. The solder joints

look a bit nicer after cleaning with water, but

it doesn't make any better in product

performance.

If you use water soluble flux, you can wash it

with soap, brush it with a tooth brush, brush

and rinse it thoroughly and dry it using a heat

gun or a hair dryer. I used a USB fan to

blow it for all night and test it on the

following day. Just let it sitting to dry

overnight may not be good enough to get rid off

moisture. Either use a heat gun for the

fast result or a small USB fan to blow it over

night. |

|

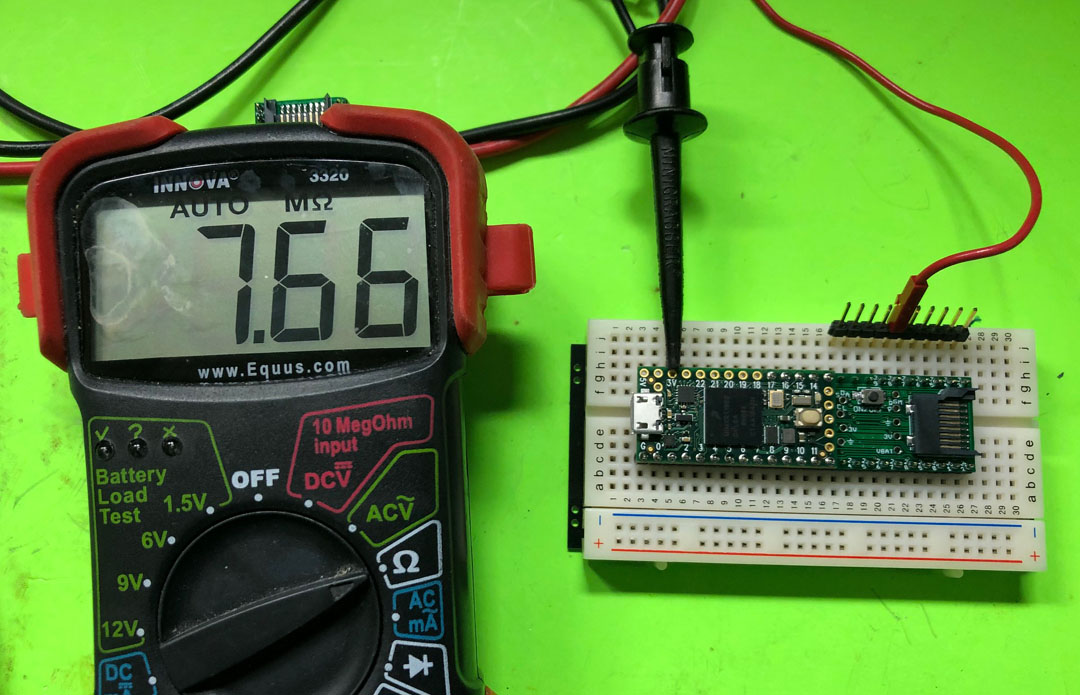

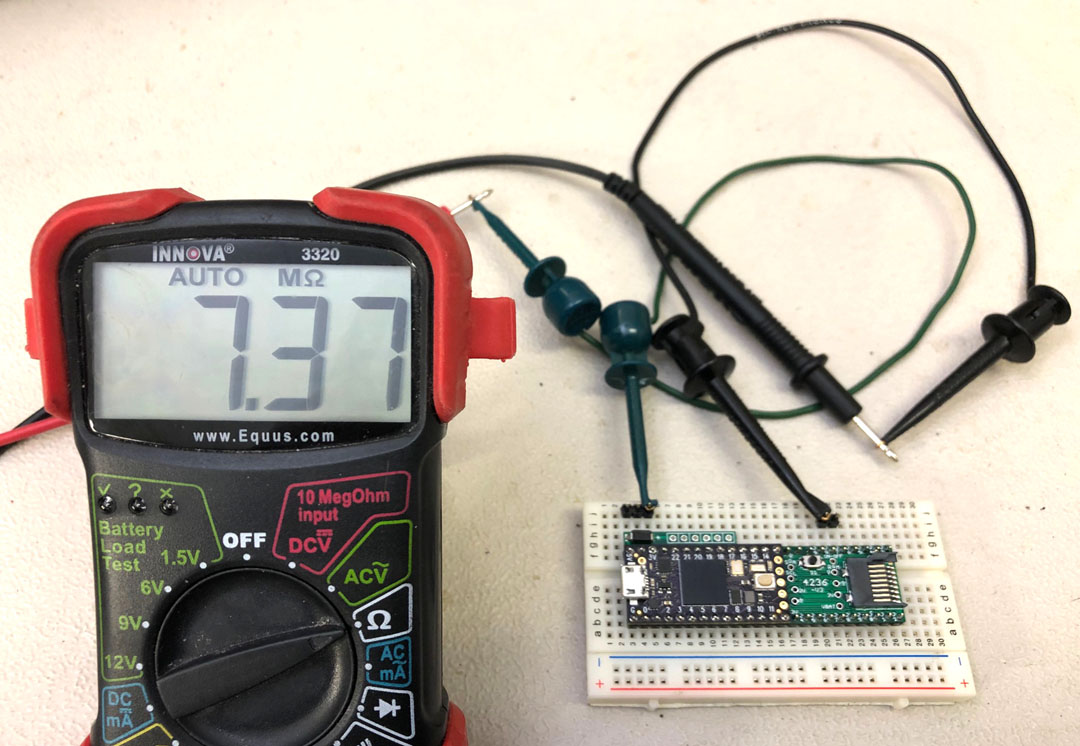

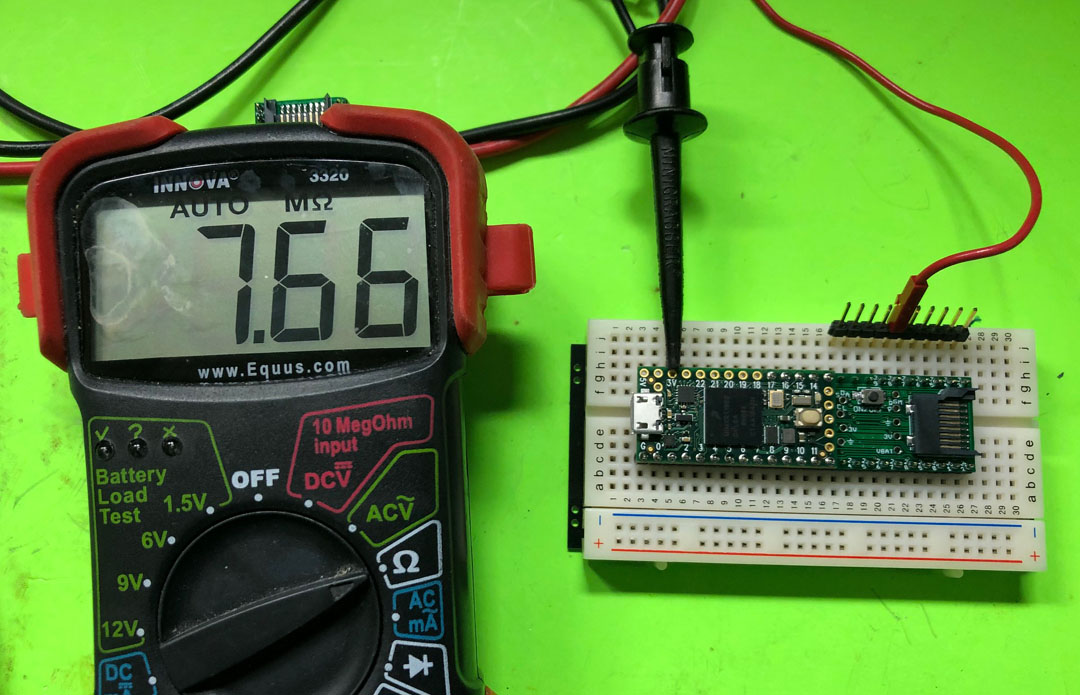

9. Before running a sketch, use a DMM to measure

resistance between each pin of D33-D39 to the

3V. It should be greater than 6 M ohms. Red

probe connects to 3V, black probe connects to a

pin. If

you get a small number, like 10K, your board is

contaminated, it won't work.

You need to see mega ohms.

Also check there should be no shorts in adjacent

pins between D33-D39 which are connected to the

1mm pitch holes. Finally check continuity

between 1mm castellated holes and pin 34- pin39.

This test was done on the rev. A board. (I did

not clean it after soldering it with the flux

just in the solder wire). If you pass this

test, you are all set to use the Teensy 4 with

this breakout board.

|

|

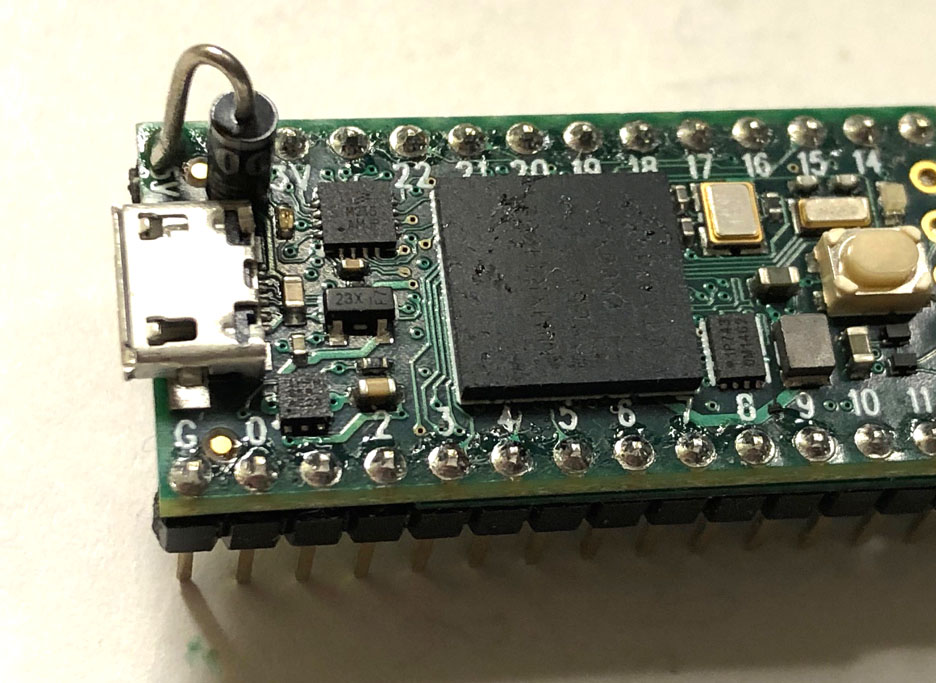

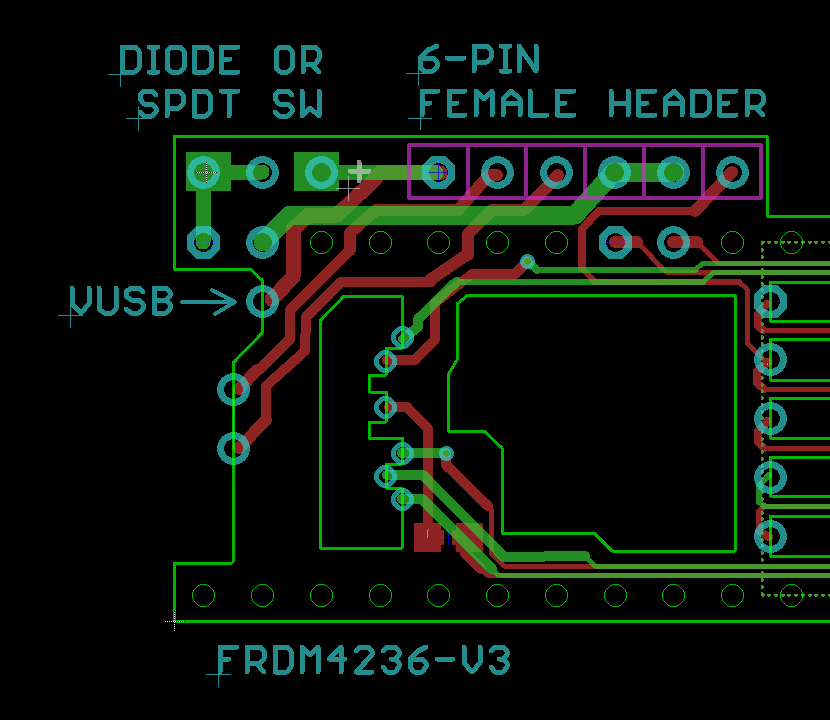

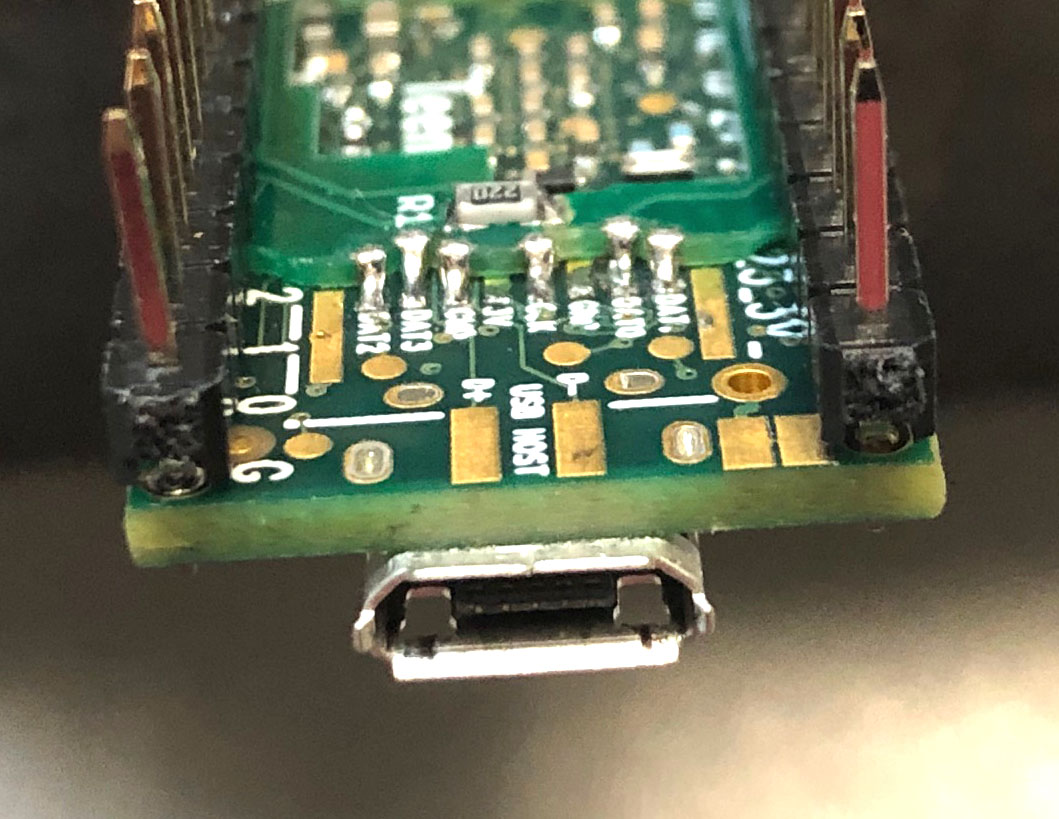

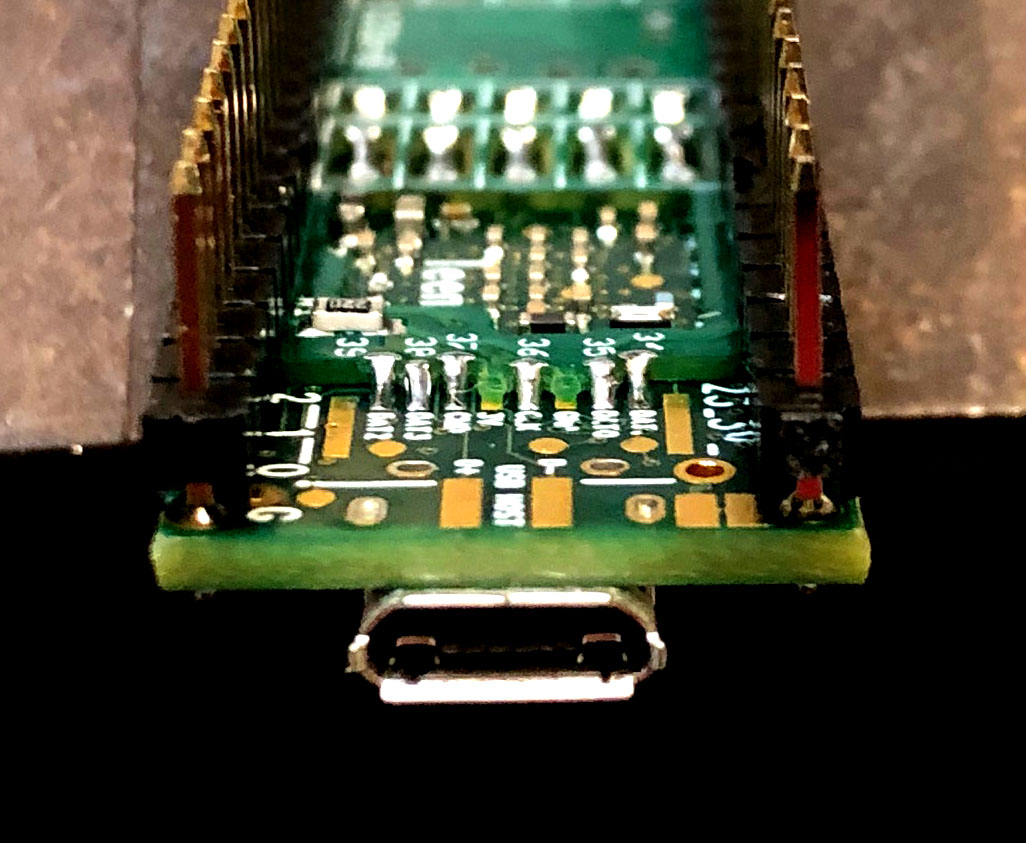

10. If you would like to separate

power sources, VUSB and Vin. The simplest way is

to add a reversing polarity protection diode.

At first, you need to cut the trace between VUSB

and VIN on the solder side.

Then, add a schottky diode.

There is room for adding an 1N5817 schottky

diode on the T4. The pad above the micro

USB jack is VUSB, just solder the anode of

1N5817 to the pad, solder the cathode of 1N5817

to the Vin. After that, you can connect

USB power and external VIN at the same time.

|

|

|

|

Teensy 4.0 with 3.6 footprint on EduBase-V2 |

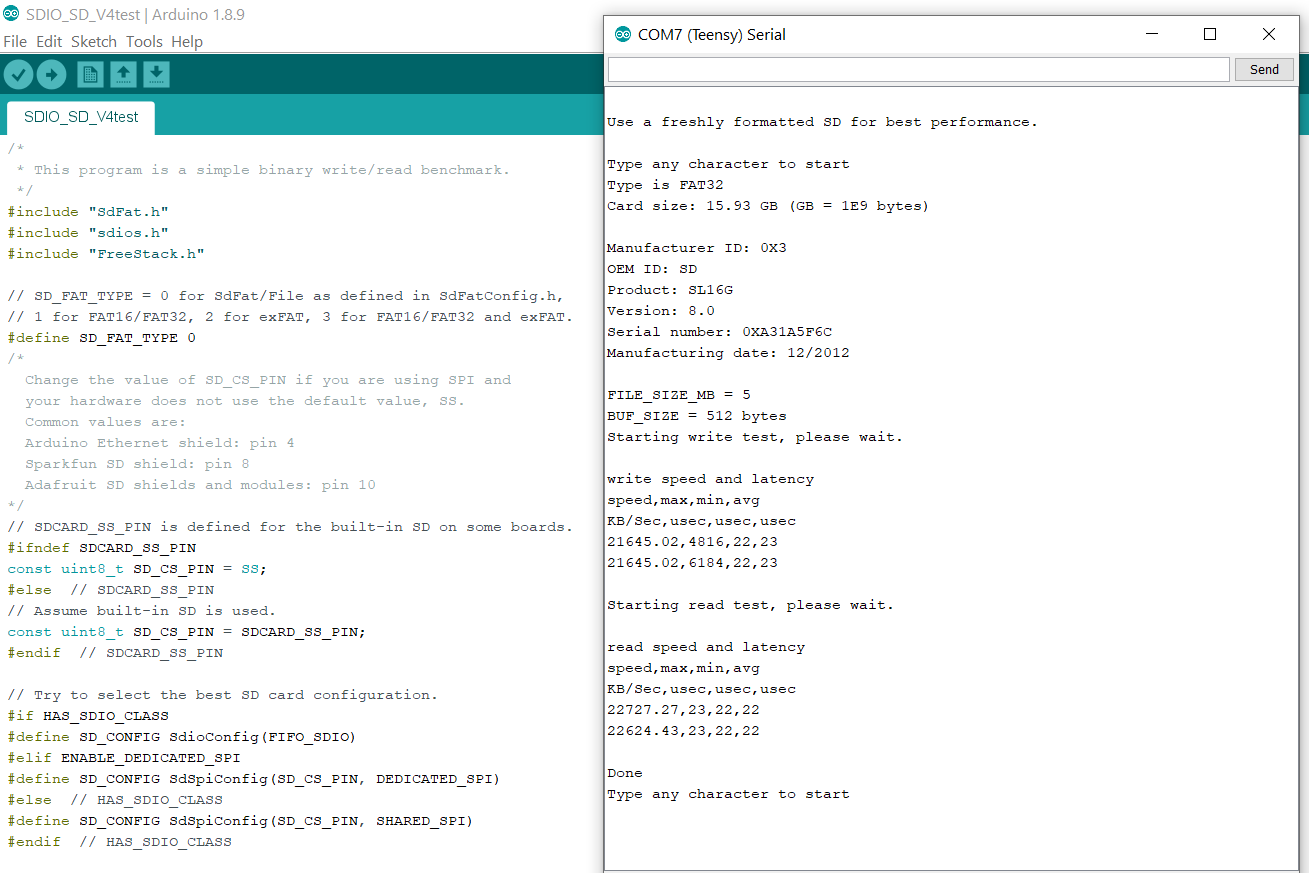

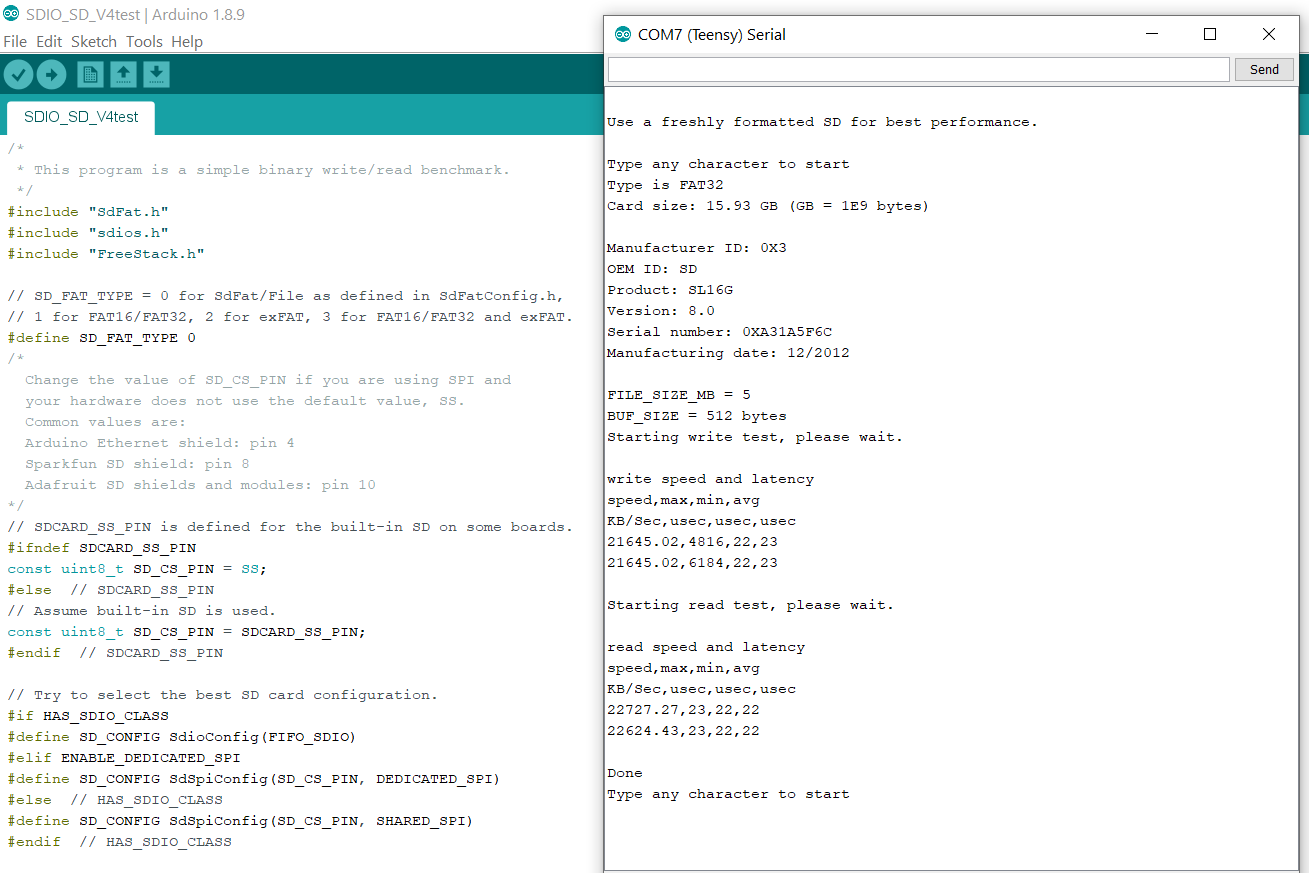

Teensy 4.0 SDIO tested OK with

Bill Greiman's SdFat 2.0.0-beta.3

|

|

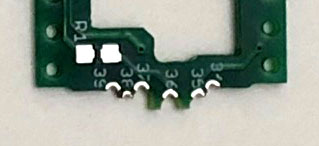

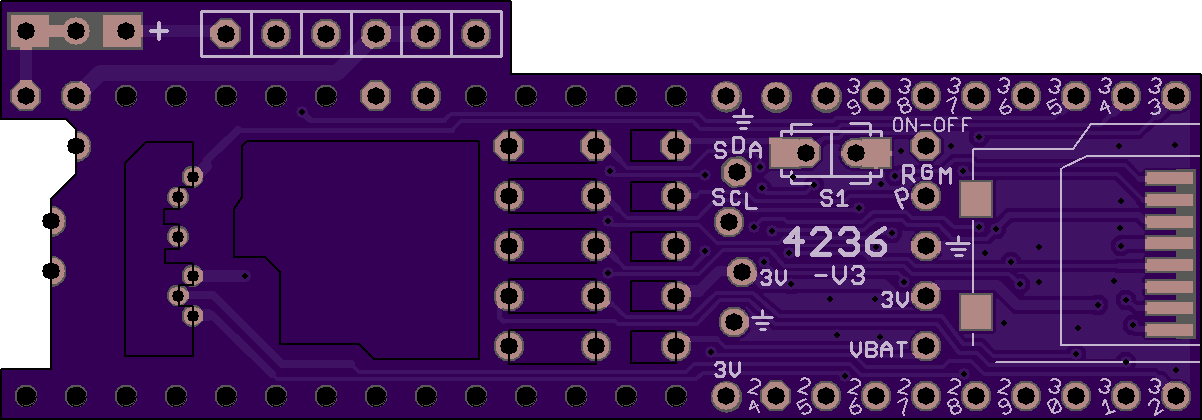

Defective

Oshpark PCB |

|

|

|

|

Just received this board from Oshpark a few days

ago. I uploaded Gerber files to Oshpark on

9/23/19, and shared a few days before I stopped

sharing. I felt that it's not a good idea to

share a untested board. Although it was tested

OK with the PCB made by a different

manufacturer. I think that I made a good

decision, otherwise someone could have wasted

money because this time the Oshpark board is

unusable.

|

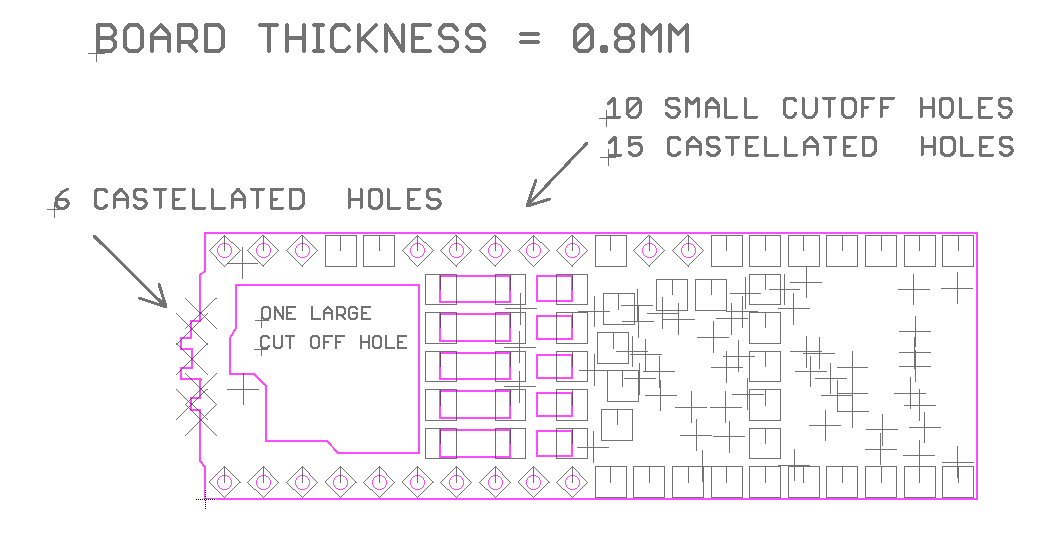

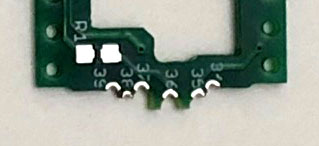

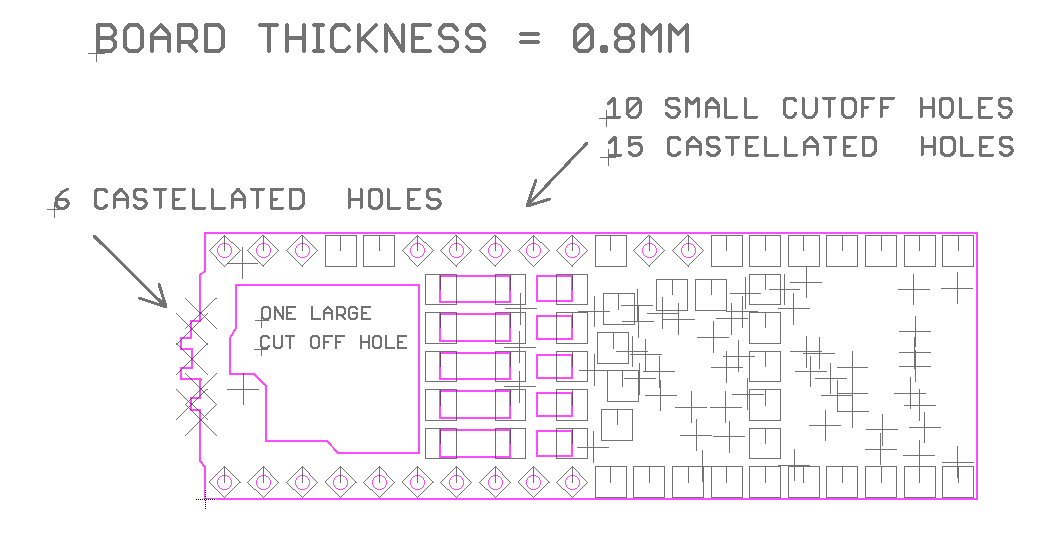

bove is the drilling data file which I specified

15 more castellated holes. The six 1mm-pitch

castellated holes were made OK, but other 15

castellated holes were not made.

If you would like to order this board, you need

to send an email to Oshpark and remind them to

route out all cut off holes.

|

|